Evaluating Plastic Pipes: Combustibility & Toxicity

Plastic piping materials have diverse chemical compositions that change from supplier to supplier and evolve over time, a factor that makes evaluating their appropriate, safe use in plumbing systems more complex. Engineers and architects use plastic pipe for many critical systems – including drain, waste, and vent (DWV), water distribution, fire suppression sprinklers, and other applications – across a wide variety of building types. These systems are installed throughout structures, making it essential to understand how they will perform during fire incidents. This report examines fire safety aspects of plastic piping materials, including one of the most commonly used, polyvinyl chloride (PVC), through a review of relevant research. An accompanying report looks at another significant issue related to plastic pipes: the risks to fire barriers associated with incorrect specification and installation of firestopping assemblies for combustible pipes.

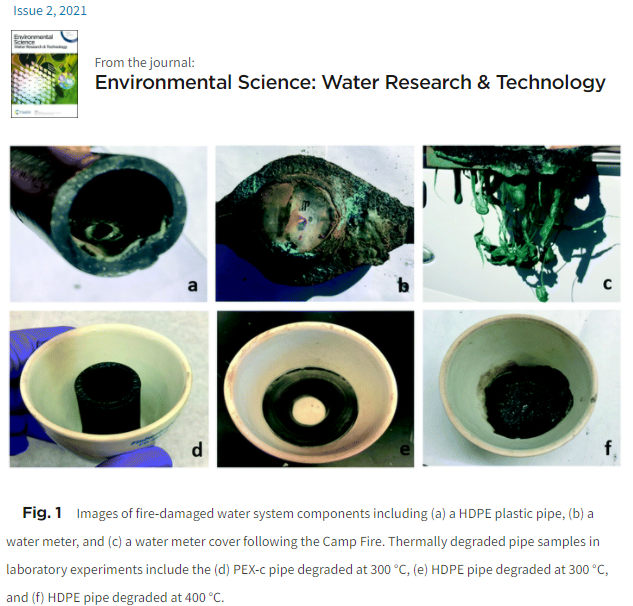

During fires, plastic pipes, foam, fabrics, and insulation all represent potent fuel sources because they are made of substances derived from petroleum. In a fire, PVC pipe starts to melt around 413 degrees Fahrenheit; it begins to combust and burn at about 790 degrees. (Structural fires routinely reach 1,500 degrees Fahrenheit, according to Firefighter Insider.)

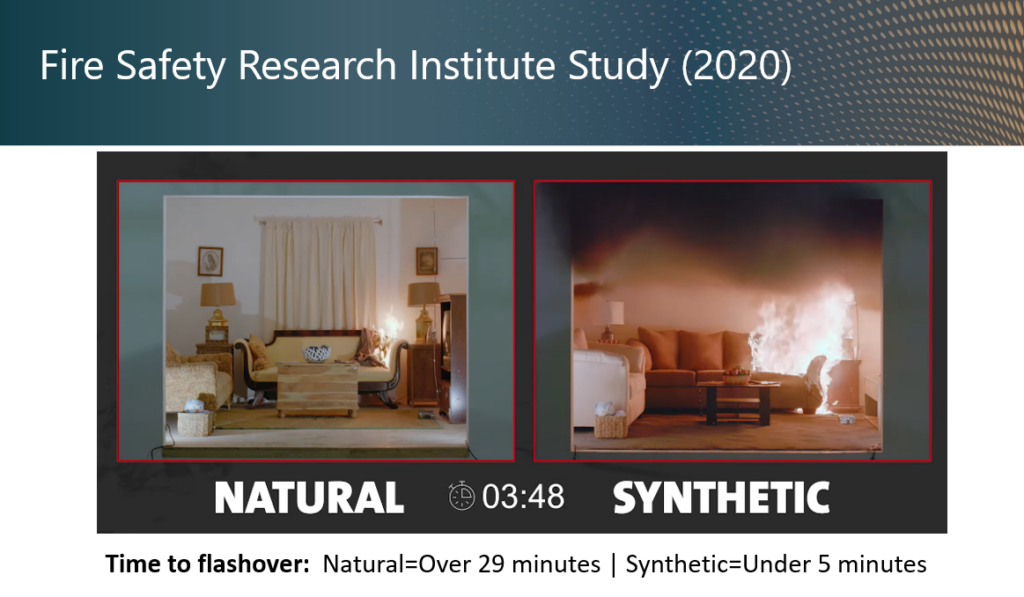

In 2020, the Fire Safety Research Institute conducted a dramatic test of flashover – the point at which a room becomes fully engulfed in flames. They conducted controlled burns of two rooms:

- A “modern” room fitted out with synthetic materials used currently, including many plastics.

- A “retro” room with materials used in the 1960s, such as wood, metal, and natural fibers.

In less than 4 minutes, the “modern” room was burning intensely and emitting toxic black smoke. The older “retro” interior was still smoldering and did not become fully engulfed for more than 29 minutes. This difference in combustibility of materials translates to fire risk, giving occupants time to escape flames and smoke. Not to mention giving firefighters and other first responders much more time to respond.

National codes require manufacturers to test many building materials, including pipe, against standards for flame spread and smoke generation. For example, the ASTM E84 standard specifies that pipe installed in plenum spaces shall not exceed a Flame Spread Index (FSI) of 25 or a Smoke Developed Index (SDI) of 50. Notably, many pipes do not pass these tests unless the methods are modified, affecting the integrity of the results.

Even if they do not modify the testing methods, manufacturers of pipe made of combustible materials must treat them with flame-retardant chemicals such as bromines and halogenated compounds to meet applicable standards. Ironically, these treatments make the smoke and chemical byproducts that come from burning plastics more toxic. A 2019 paper “Releases of Fire-Derived Contaminants from Polymer Pipes Made of Polyvinyl Chloride” published in the journal Toxics details these issues:

…to assess the human exposure risks from the release of contaminants from water pipes made of polyvinyl chloride (PVC), experiments were carried out by subjecting the PVC pipe material to burning and leaching conditions followed by analysis of the emission and leachate samples. The emissions of burning pipes were analyzed by both infrared spectrometry and gas chromatography-mass spectrometry (GC-MS). The emission test results indicate the presence of chlorinated components including chlorine dioxide, methyl chloride, methylene chloride, allyl chloride, vinyl chloride, ethyl chloride, 1-chlorobutane, tetrachloroethylene, chlorobenzene, and hydrogen chloride were detected in the emissions of burning PVC pipes. Furthermore, the concentrations of benzene, 1,3-butadiene, methyl methacrylate, carbon monoxide, acrolein, and formaldehyde were found at levels capable of affecting human health adversely.

An earlier report corroborates these findings, identifying the types and kinds of chemicals emitted by burning plastic pipe. In this study, researchers installed plastic pipes in a one-hour fire resistance assembly and placed it below a hood to collect the smoke and gases produced. They then conducted a one-hour controlled burn, analyzing the results using Fourier transform infrared spectroscopy (FITR). The results found the following toxic substances:

- Hydrogen chloride

- Hydrogen fluoride

- Hydrogen bromide

- Hydrogen cyanide

- Nitrogen oxide

- Nitrogen dioxide

- Carbon dioxide

- Carbon monoxide

- Sulfur dioxide

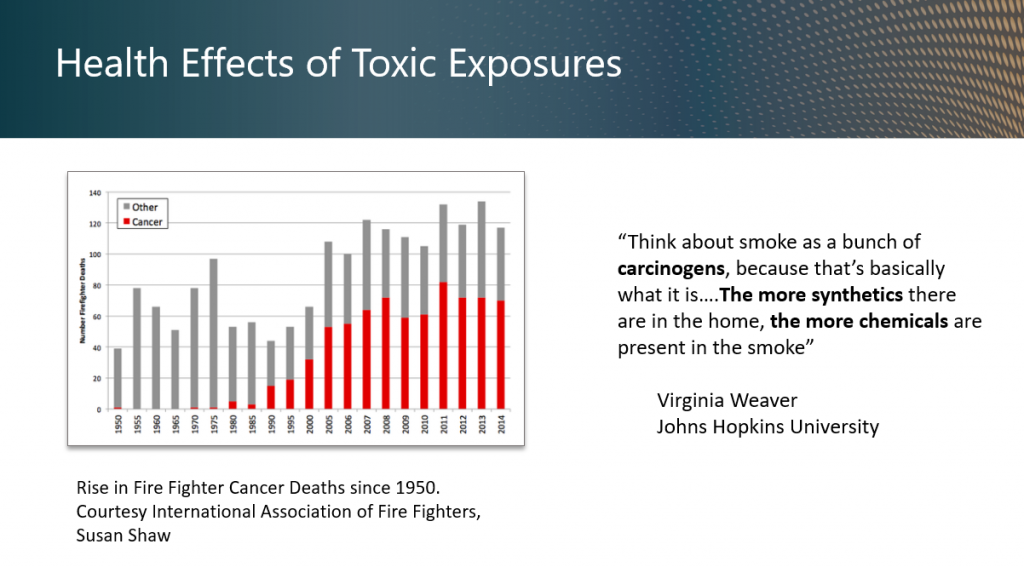

Even short-duration exposures to these substances can lead to asphyxiation and poisoning of occupants trying to escape a fire. As significant, studies of firefighter health find that the smoke and soot from fires increases incidence of many cancers, including those affecting the lungs, brain, heart, digestive, and reproductive systems. According to the National Institute of Occupational Safety and Health (NIOSH), cancer has become the leading killer of active firefighters, a disturbing trend in line with the growth of plastic content in buildings. A five-year study looking at cancer in firefighters determined they are at higher risk of cancer diagnoses and deaths than similar individuals in the wider population.

These and other research studies raise questions about where and how much plastic pipe is safe to install in buildings, especially those used by children, the elderly, and other vulnerable individuals. The level of fire risk posed by combustible plastic pipe and its toxic chemical content must be considered alongside factors such as chemical compatibility, firestopping requirements, and other issues.