Research Shows Risks of Plastic Pipes in Fires

Recent fire testing from the Copper Sustainability Partnership (CuSP) reinforces our findings that combustible plastic plumbing materials pose significant risks in fire conditions. Their results highlight factors that architects and engineers must understand when considering how pipe material choices impact fire risks, building integrity, and the safety of occupants and first responders.

Fire Performance of Plastic Pipes

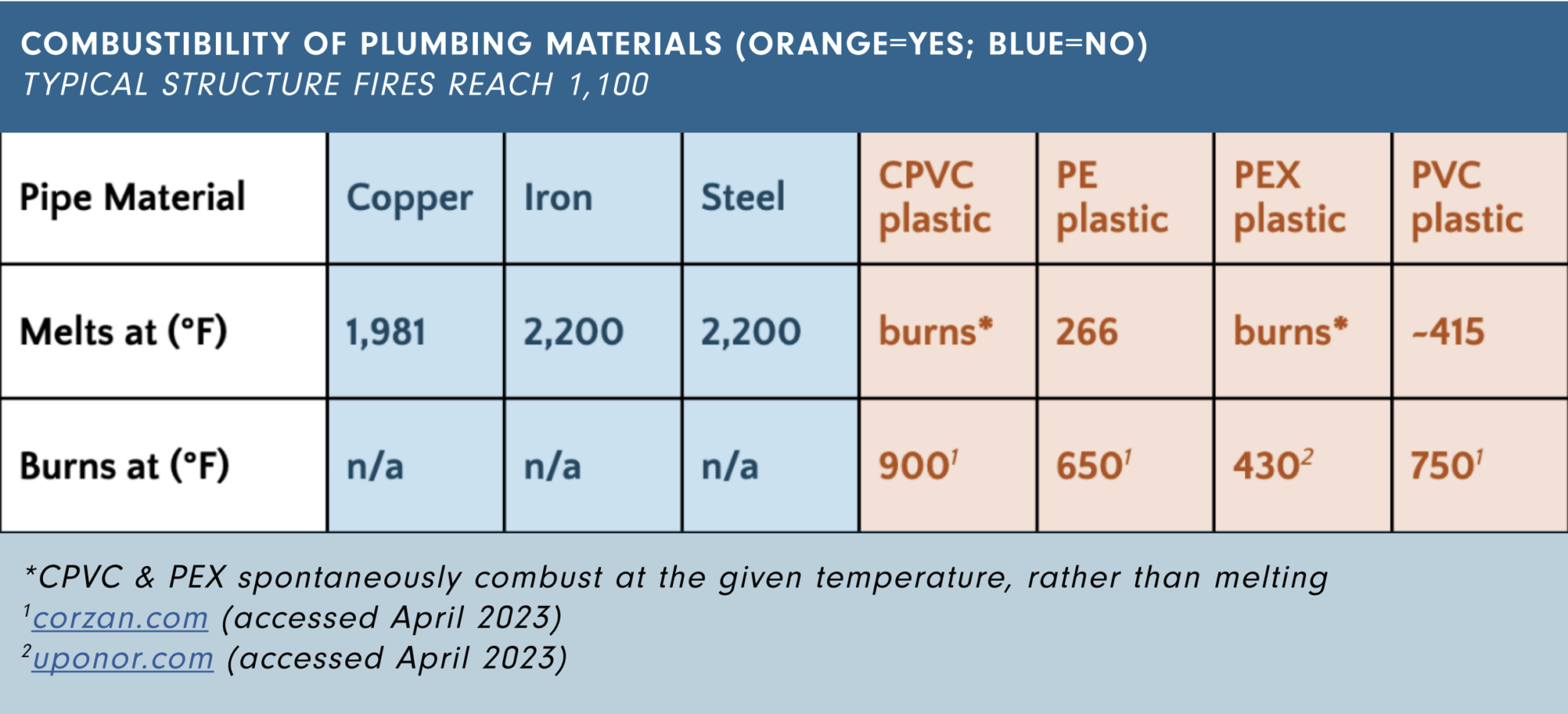

CuSP’s burn testing showed that plastic pipes fail rapidly under heat, creating openings that enable flames and smoke to penetrate floors and walls. Plastic pipes such as PVC, CPVC, PEX, and ABS begin to melt and burn at temperatures far below those commonly reached in structure fires, compromising containment and allowing fire to spread through walls, ceilings, and floors.

Even when firestopping materials are applied, their effectiveness depends on installation quality and maintenance. As our report on Firestopping Pipe Penetrations explains, the higher complexity of firestopping combustible pipe penetrations increases the likelihood of errors. “There is quite a lengthy list of items which can result in problems with the installation of firestopping materials,” says firestopping expert Eirene Knott, explaining that issues with “any one of these items can contribute to a two-hour wall being reduced to a four-minute wall.”

Toxic Smoke and First Responder Exposure

Toxic Smoke and First Responder Exposure

The CuSP testing report also presents disturbing data on toxic chemicals released by burning plastic pipes, including hydrogen cyanide and carbon monoxide. These findings echo similar results of independent burn tests of PVC pipe that showed plastic pipes emitted hydrogen chloride gas at levels that exceeded the Acute REL and 1-hr SPEGL concentrations in 14 minutes. Controlled burn tests by the Fire Safety Institute show similar results for other synthetic materials; their video records thick black clouds of smoke filling rooms within minutes of a fire incident. Toxic chemicals can corrode lung tissue, cause severe respiratory damage, and increase cancer risks faced by firefighters and other first responders. The firefighter industry has called for limits on use of plastic pipes in buildings due to the long-term exposure they face from toxic byproducts of plastic combustion.

Water Contamination Following Fires

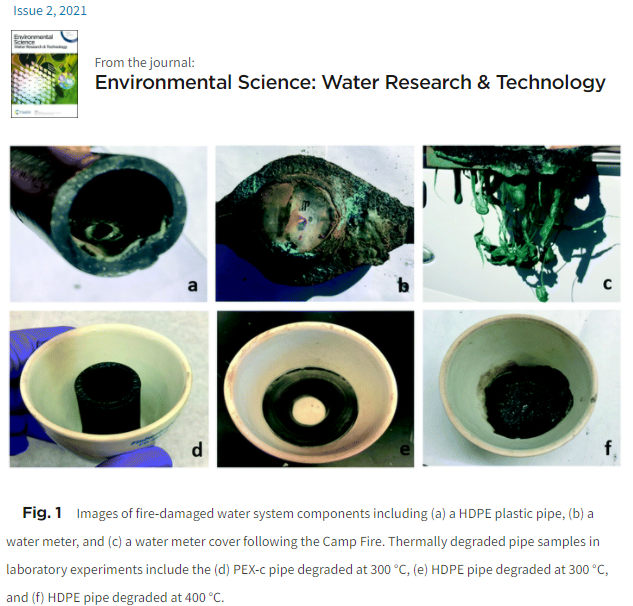

Beyond immediate fire risks, burned plastic pipes can introduce chemical contaminants into the water supply. In the aftermath of wildfires across California, plastic pipes have leached benzene and volatile organic compounds into drinking water systems, rendering them unsafe. Research from Purdue’s Andrew Whelton and others raises further questions about the use of PVC, PE, and other plastics for critical infrastructure in buildings and across communities. According to the paper they published in Environmental Science: Water Research & Technology, “Plastic pipe thermal degradation can be a source of VOC and SVOC drinking water contamination… Further, the implications of plastic pipe caused drinking water contamination extends beyond fire-prone regions to any structure fire where plastic pipes may have experienced elevated temperatures.”

Beyond immediate fire risks, burned plastic pipes can introduce chemical contaminants into the water supply. In the aftermath of wildfires across California, plastic pipes have leached benzene and volatile organic compounds into drinking water systems, rendering them unsafe. Research from Purdue’s Andrew Whelton and others raises further questions about the use of PVC, PE, and other plastics for critical infrastructure in buildings and across communities. According to the paper they published in Environmental Science: Water Research & Technology, “Plastic pipe thermal degradation can be a source of VOC and SVOC drinking water contamination… Further, the implications of plastic pipe caused drinking water contamination extends beyond fire-prone regions to any structure fire where plastic pipes may have experienced elevated temperatures.”

Building Codes, and Fire Testing Loopholes

Despite these hazards, it appears that some manufacturers of plastic pipes have sought workarounds to safeguards intended to limit fire risks. An industry discussion of IAPMO standards expressed concern about “modified” ASTM E84 testing that does not reflect the specified conditions. Further, a recent scathing critique from Poly Pipe News called out plastics groups for “blatant misrepresentation” and “categorically false” information and said the construction and plumbing industries “deserve better.”

The Path to Fire-Safe Design

Testing and other research to date makes it clear that material choices matter for those designing and constructing resilient, fire-safe buildings. Current assessments of risks make a case that the industry should prioritize noncombustible metal piping materials as a key step toward protecting building occupants and first responders, reducing risks and liability, and ensuring the integrity of piping systems after fires occur.