Sprinkler System Piping:

Issues & Recommendations

Overview

Fire-sprinkler systems are a fundamental component of modern fire protection strategies, offering active protection that enhances occupant safety, minimizes structural damage, and ensures compliance with building codes. When properly designed, installed, and maintained, these systems can effectively control or extinguish fires before they escalate, reducing threats to life and property. The pipe materials that comprise such systems have significant impacts on their performance and reliability, so integrating these critical life-safety systems into a building’s design requires careful consideration of factors that go beyond simply meeting applicable codes.

This report provides a comprehensive overview of system components, design considerations, and material options associated with fire-sprinkler systems. It is based on guidance from the American Society of Plumbing Engineers (ASPE), the National Fire Protection Association (NFPA), and other technical and industry sources.

System Types

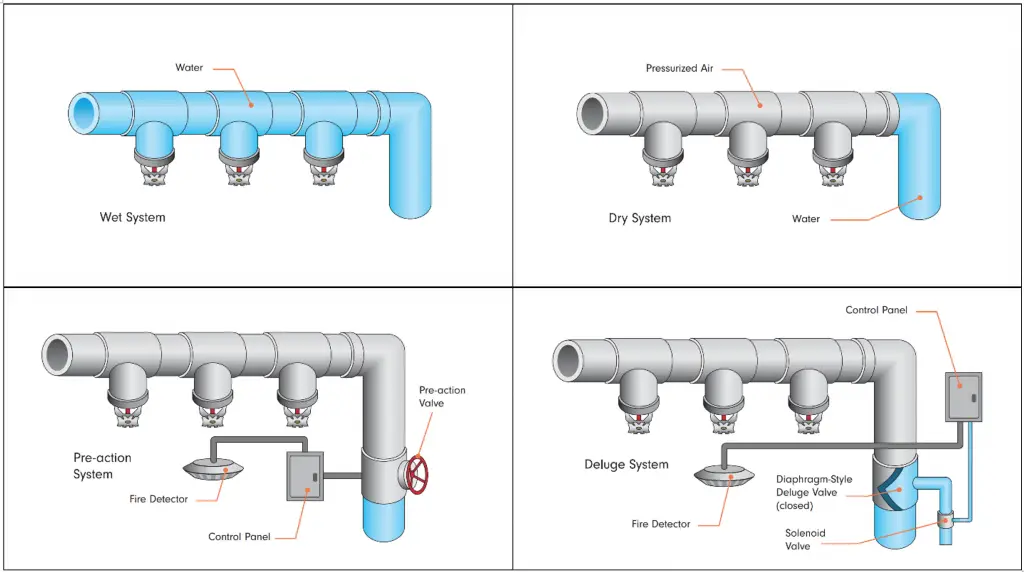

Sprinkler systems fall into four categories.

- Wet pipe systems contain water at all times; individual sprinklers activate when triggered and discharge water to the area they cover.

- Dry pipe systems contain pressurized air rather than water. When triggered, the system fills with water and sprinklers activate. They are used when freezing may be a concern.

- Pre-action systems discharge water only after a separate trigger activates, protecting against accidental discharge, and are used in sensitive areas such as museums or document archives.

- Deluge systems release water from all sprinklers simultaneously when the system activates and are used in high-hazard areas.

Material Considerations

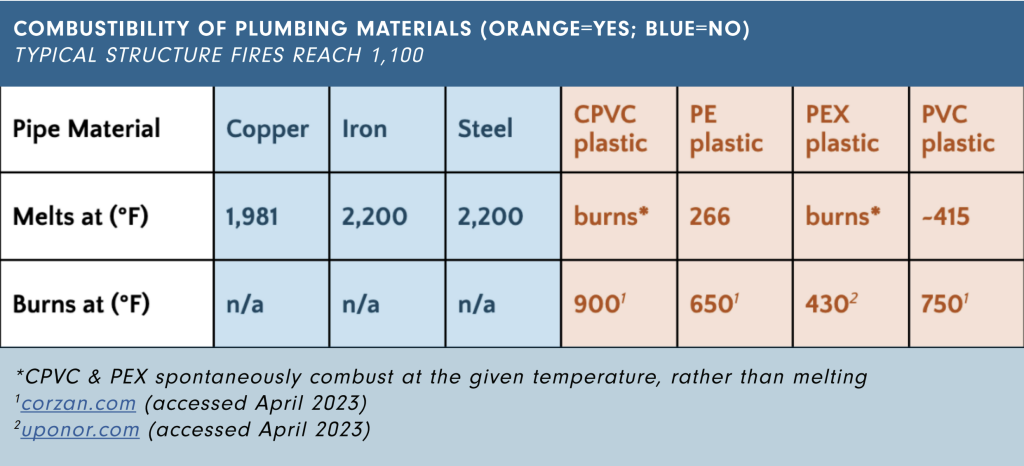

Various pipe materials have different characteristics that impact the performance and risks when used for fire-sprinkler systems. One of the most significant differences is combustibility. Structure fires reach temperatures of 1,100° Fahrenheit. The chart below shows how pipe materials perform at high temperatures. Metal pipes resist damage; plastic pipes will melt or burn.

Other pipe material characteristics also affect the performance and maintenance needs of sprinkler systems.

SteelPros:

Cons:

|  |

CopperPros:

Cons:

|  |

CPVC (Chlorinated Polyvinyl Chloride)Pros:

Cons:

|  |

PEX (Cross-Linked Polyethylene)Pros:

Cons:

|  |

Code Compliance

The NFPA administers a number of key standards that apply to a range of building types both in the U.S. and internationally:

NFPA 13: This is the industry’s foundational standard for the design and installation of fire sprinkler systems in commercial, industrial, and multi-family residential buildings. First published in 1896 in response to increasing losses from structure fires during the industrial revolution, NFPA 13 has evolved through decades of revisions and now incorporates scientific research, fire modeling, and modern material performance standards. It sets requirements for system design, water supply, component performance, installation practices, and maintenance.

NFPA 13: This is the industry’s foundational standard for the design and installation of fire sprinkler systems in commercial, industrial, and multi-family residential buildings. First published in 1896 in response to increasing losses from structure fires during the industrial revolution, NFPA 13 has evolved through decades of revisions and now incorporates scientific research, fire modeling, and modern material performance standards. It sets requirements for system design, water supply, component performance, installation practices, and maintenance.- NFPA 13R: Tailored for residential buildings up to four stories in height, with allowances that reflect lower risk profiles while maintaining core safety principles.

- NFPA 13D: Applies to one- and two-family dwellings and manufactured homes, with simplified design criteria to support more affordable residential protection.

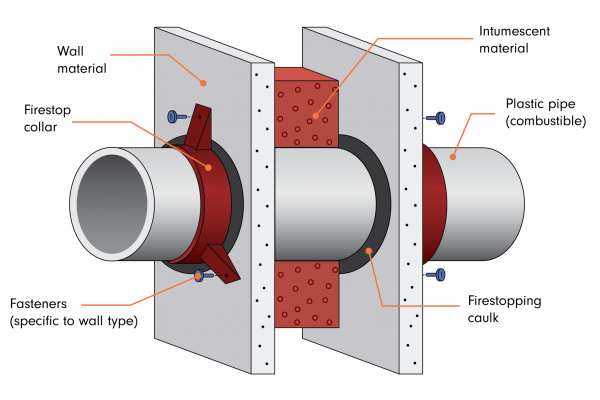

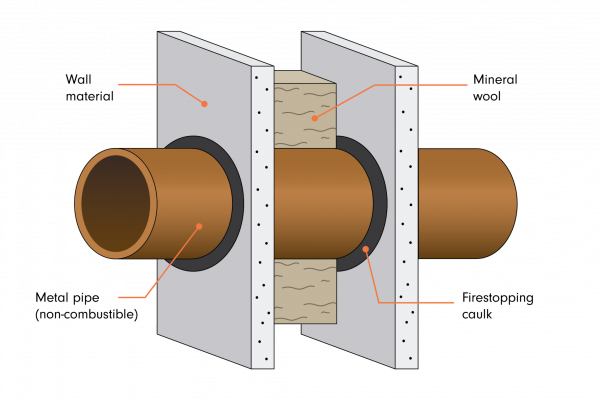

Fire codes also require penetrations through fire-rated walls and floors to be sealed using approved firestopping systems. This is more complex with plastic piping, which melts in a fire. These products require intumescent wraps or other specialized systems that activate during fires and seal gaps created by damage to the plastic pipe.

Sprinkler-system piping that passes through plenum spaces must meet additional code requirements and fire-safety standards, including the Uniform Mechanical Code (UMC), NFPA 90A and ASTM E84 in the U.S., and ULC S102 and S102.2 in Canada. (Note that the UL has stated ULC standards are not acceptable for the U.S.) Materials must meet strict flame-spread and smoke-production limits. For example, the ASTM E84 “Surface Burning Characteristics of Building Materials” test sets a 25/50 rule limiting flame spread and smoke development for materials used in plenum spaces. To comply with E84 for plenum applications, sprinkler piping and assemblies must have a flame spread index of 25 or less and a smoke-development index of 50 or less.

Sprinkler-system piping that passes through plenum spaces must meet additional code requirements and fire-safety standards, including the Uniform Mechanical Code (UMC), NFPA 90A and ASTM E84 in the U.S., and ULC S102 and S102.2 in Canada. (Note that the UL has stated ULC standards are not acceptable for the U.S.) Materials must meet strict flame-spread and smoke-production limits. For example, the ASTM E84 “Surface Burning Characteristics of Building Materials” test sets a 25/50 rule limiting flame spread and smoke development for materials used in plenum spaces. To comply with E84 for plenum applications, sprinkler piping and assemblies must have a flame spread index of 25 or less and a smoke-development index of 50 or less.

Non-combustible materials like copper and steel typically meet the 25/50 rule without additional fireproofing. As noted above, their melting points are far above the range of a normal structural fire. By contrast, plastic pipes that do not meet this rating on their own must be enclosed in a noncombustible raceway or be installed as an assembly. Typical assemblies will cover the plastic pipe with plenum wrap, a fire-rated insulation material made from inorganic fibers encased in scrim-reinforced foil. The insulating wrap is meant to ensure the assembly as a whole meets the 25/50 requirement specified by building codes.

Because of this, Chapter 6 of the UMC requires that each combination of “pipe or duct and its related insulation, coatings, and adhesives are tested as a composite assembly.” This important distinction in the code makes it unacceptable to install an assembly unless the specific components used by a project have been put together, tested as a whole, and found to be compliant with the 25/50 rule.

Maintenance Considerations

Fire-sprinkler systems must remain functional over decades. Maintenance includes inspections for corrosion, leaks, or mechanical wear. Sprinkler systems running through plenum spaces require additional consideration, because these areas are typically crowded with ducts, pipes, wiring, and other systems, increasing risk that damage or maintenance of one system will affect other systems. The issue of chemical compatibility is a particular concern. The latest Plumbing Specification Guide found many plastic pipes have “higher susceptibility to damage when exposed to chemicals,” with manufacturers listing “countless” construction and maintenance products that must not be used with plastic pipe. Such lists include specific caulks and sealants, cleaning solutions, pipe clamps and tape, lubricants and oils, waterproofing materials, spray foam, and firestopping materials, among other substances.

Fire-sprinkler systems must remain functional over decades. Maintenance includes inspections for corrosion, leaks, or mechanical wear. Sprinkler systems running through plenum spaces require additional consideration, because these areas are typically crowded with ducts, pipes, wiring, and other systems, increasing risk that damage or maintenance of one system will affect other systems. The issue of chemical compatibility is a particular concern. The latest Plumbing Specification Guide found many plastic pipes have “higher susceptibility to damage when exposed to chemicals,” with manufacturers listing “countless” construction and maintenance products that must not be used with plastic pipe. Such lists include specific caulks and sealants, cleaning solutions, pipe clamps and tape, lubricants and oils, waterproofing materials, spray foam, and firestopping materials, among other substances.

Other Considerations

- Aesthetics: In finished spaces, designers may choose concealed heads, painted escutcheons, or flush-mounted systems. Thoughtful integration can preserve visual appeal while maintaining function.

- Building Layout Integration: Ceiling height, structure, and obstructions must allow for effective sprinkler placement. Coordination with lighting, HVAC, and architectural elements ensures coverage is not compromised. As described above, sprinkler systems in plenum spaces – where other mechanical systems and wiring are routed – materials must comply with fire-rating requirements.

- Sustainability: Architects, engineers, and construction professionals increasingly prioritize sustainability among their project goals. The most significant difference of among types of pipes comes at the end of product life. Virtually all plastic pipes are engineered for single use, and recycling rates for plastic pipes are virtually zero. Plastic waste gets landfilled, adding to plastic pollution, or incinerated, increasing carbon footprint and toxic and microplastic emissions. By contrast, copper, iron, and steel have recycling rates of 60% or more, allowing these materials to be reused infinitely.

Recommendations

Building teams serve a key role in selecting, coordinating, and integrating fire-sprinkler systems that meet safety standards without compromising building design. To ensure building integrity and most importantly, occupant safety, they should incorporate the following guidelines into their design process.

Building teams serve a key role in selecting, coordinating, and integrating fire-sprinkler systems that meet safety standards without compromising building design. To ensure building integrity and most importantly, occupant safety, they should incorporate the following guidelines into their design process.

- First, teams should take a holistic approach when evaluating pipe materials, considering issues such as fire resistance, reliability, maintenance concerns, and long-term durability, as or more important than cost and installation.

- Second, they should incorporate system layout early in the design process, coordinating pipe routes and sprinkler coverage with other building elements to avoid costly conflicts and ensure code compliance. This includes addressing penetrations through fire-rated assemblies and selecting firestopping materials appropriate for the pipe type.

- Third, they must consider the long-term performance of the system. Lower-cost piping may offer initial savings but bring with it more complex installation requirements and greater liability, especially in plenum spaces and where chemical exposure is possible.

- Finally, they should collaborate with industry experts, fire-system specialists, and reputable suppliers. Fire-sprinkler systems vary by application, occupancy, and regional code, making partnerships an important success factor for meeting project goals and serving occupant needs.

The following sources may also prove helpful:

- The National Fire Protection Association (NFPA): The NFPA is a global nonprofit organization devoted to eliminating death, injury, and property loss from fire and related hazards. NFPA 13 is one of its most widely adopted codes, serving as the foundation for fire-sprinkler system design. The organization provides standards, training, certification, and educational resources. Learn more at: https://www.nfpa.org

- Underwriters Laboratories (UL): UL is an independent safety science company that performs rigorous testing of fire protection products, including piping, valves, and fire-sprinkler components. Its UL certification mark is an essential benchmark for product compliance with safety standards. Learn more at: https://www.ul.com

- Safe Piping Matters: A public education initiative focused on the health, safety, and performance implications of piping materials in buildings. Reports on firestopping systems and the Plumbing Specification Guide provide valuable insights for architects and designers.

- FM Approvals: A third-party testing and certification organization known for its rigorous performance-based standards. FM Approvals evaluates sprinkler system components under real-world fire conditions to ensure reliable operation. Learn more at: https://www.fmapprovals.com

- The Fire Safety Research Institute (FSRI): FSRI is part of UL’s Fire Safety division and conducts cutting-edge research on fire dynamics, material performance, and fire suppression systems. Their work supports science-based improvements to codes, standards, and emergency response. Learn more at: https://www.fsri.org