Fire Safety Issues of Piping Systems

Highlights from the BSS Industry Conference – Part 2

As mentioned in part 1 of this recap, which focused on sustainability of various pipe materials, we had good discussions with contractors, engineers, and manufacturers at the BSS Conference in London. For fire safety, research shows makes an equally compelling case that the types of pipe in a building matter.

As mentioned in part 1 of this recap, which focused on sustainability of various pipe materials, we had good discussions with contractors, engineers, and manufacturers at the BSS Conference in London. For fire safety, research shows makes an equally compelling case that the types of pipe in a building matter.

The discussions on this topic focused on these questions:

- Where can we learn more about the effects of piping materials on fire safety?

- How common are firestopping problems in buildings that are already constructed and in use?

The answers are below, but for context, let’s first go over some key points, starting with

Fire Safety

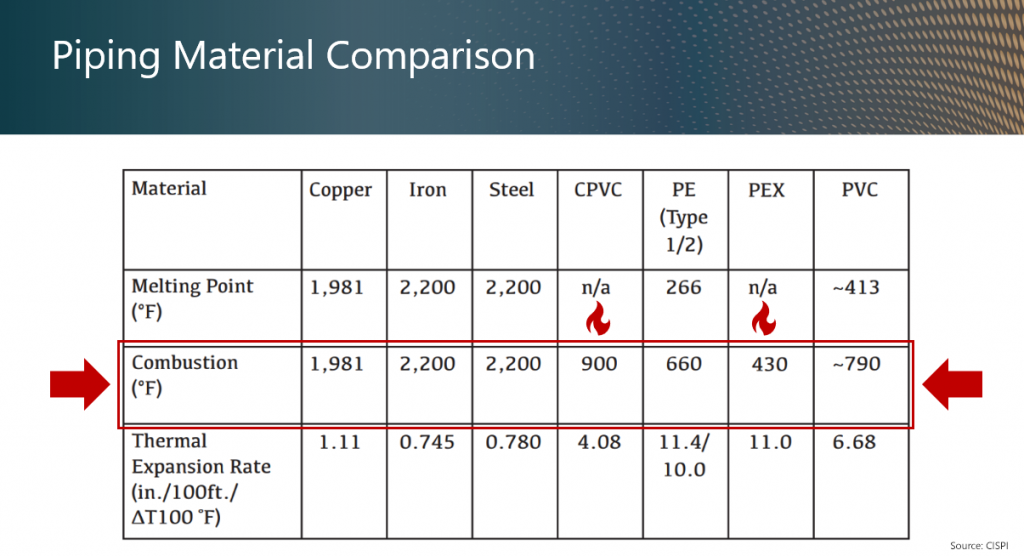

Piping materials show clear distinctions in how they perform in fires. Basically this difference comes down to one thing: combustibility. The chart below shows temperatures at which various types of pipes will melt and catch fire. As a point of reference, an average structural fire generates temperatures up to about 1500 degrees Fahrenheit.

Metal pipes are not combustible at this level though they will melt when exposed to very extreme heat. By contrast, we can see that plastic pipes burn at temperatures much lower than happen in a fire, starting around 400 degrees Fahrenheit. Some plastic pipes also will melt before they burn, which can create other issues, including failures in exposed spaces or walls.

Toxins from Plastic Pipes

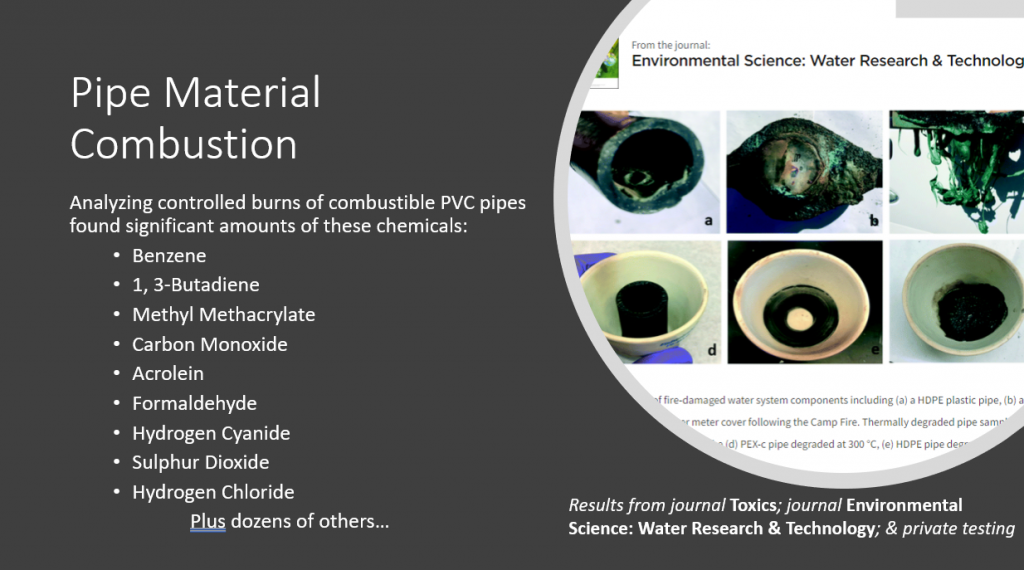

What happens when plastic pipes burn? A number of researchers have studied this question. Using chemical analysis, they identified dozens of volatile organic chemicals released into smoke and soot and toxins like formaldehyde and hydrogen cyanide. Purdue engineering professor Andrew Whelton has also studied what gets released into water from melted and burned plastic pipes. He found carcinogenic benzene at levels 40,000 times the safe limit as well as scores of other chemicals with negative health effects.

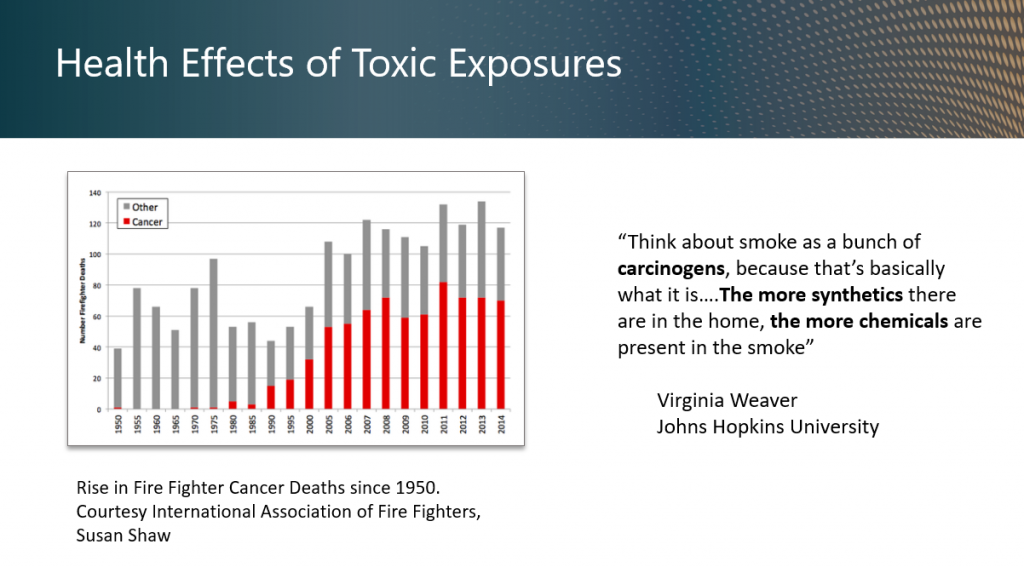

Breathing the smoke and fumes from burning plastic or having your skin absorb them can cause acute reactions like nausea, burning eyes, and lung irritation in the short term. But the long term effects of exposures to chemicals released in fires is more troubling including cancers of the liver, brain, and reproductive systems. A study of firefighter deaths shows these types of cancers rising steadily since the 1950s roughly corresponding to the growth in use of plastics in buildings.

Should we continue plasticizing the environments where we live and work?

Firestopping

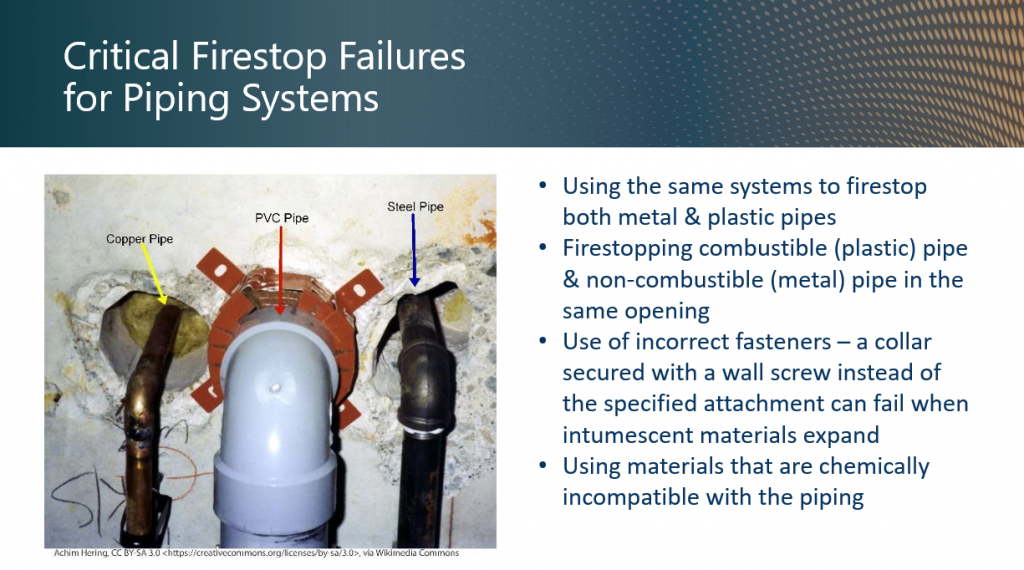

We then talked about firestopping. Firestops work to restore the integrity of passive fire barriers between walls and vertical levels of buildings penetrated by pipes, electrical, HVAC and other building systems. If they don’t work, the firewalls might as well not be there. A pencil-sized hole in a firewall will allow enough smoke to pass through in minutes to overcome anyone on the other side

In order to work, each and every firestop system must account for the materials and situations they are designed cover. And while codes prescribe exact formulas for installation, experts in the field see a lot of errors.

For example the image above shows that the large waste pipe in the center is fitted with a collar that should secure it to the wall. This is so that in a fire, the expansion of intumescent fire materials will seal off the hole. Since this one isn’t screwed to the firewall however, the expansion will just push the collar and pipe away, leaving a gap for smoke and heat.

Combustible plastic pipes require more complicated fire stop systems than non-combustible metal ones leaving more room for error. That’s one reason why combustible pipes aren’t allowed in hospitals, many high rises and other buildings where safety is critical.

In what other types of buildings should we minimize use of these systems to increase fire resilience? Multi-family housing? Senior living? Schools and daycare facilities?

Now, the Q&A…

Where can we learn more about the effects of piping materials on fire safety?

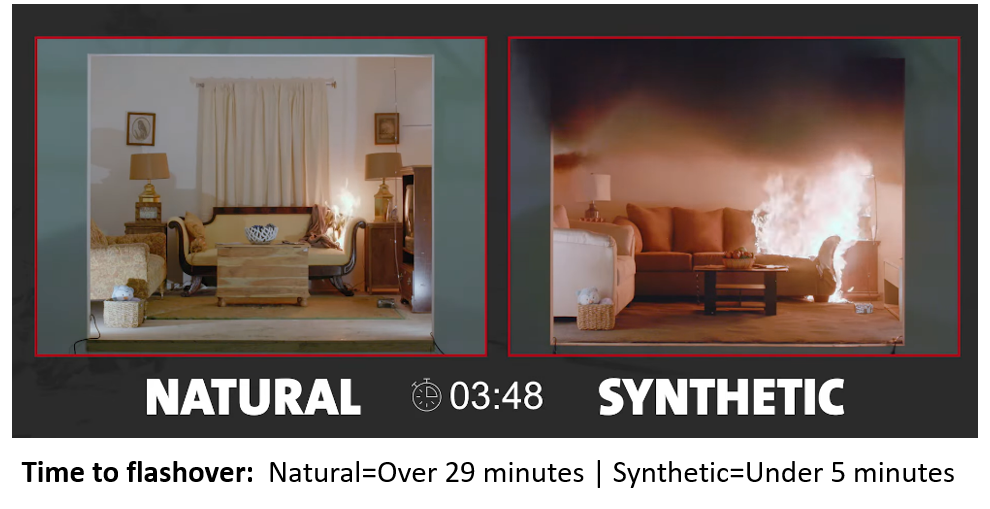

The Fire Safety Research Institute has produced one of the best illustrations showing why combustibility matters for fire safety. The screenshot below comes from this striking video, which shows how two different rooms were affected in a burn test.

- The room on the right was designed with materials from the last 20 years, including more synthetics like plastic laminates, cushions containing plastic foam, and polyester-type fabrics. Despite the use of flame retardant additives, the plastics and other synthetics in this room became fully engulfed in less than 5 minutes. That leaves anyone who might have been inside very little time to escape and firefighters virtually no time to respond. In addition, the smoke in the synthetic room was thicker, and as we know from research, it is more deadly as well.

- The room on the left was designed to mimic a room with materials from the 1960s with less flammable materials like wood, metal, cotton, wool, and other naturally sourced fabrics. This one lasted more than 29 minutes before it was fully burning.

Let’s remember, plastic pipes are also made of plastic, and as we saw from the chart, they will burn, starting with exposed pipes and then spreading into walls and upper floors of a structure.

How common are firestopping problems in buildings that are already constructed and in use?

Sharron Halpert, a firestopping expert who publishes great information on firestopping for contractors and inspectors, has dedicated a whole section of her excellent website to Classic Mistakes of firestopping. Take a look at the photos she posts, and you’ll get a sense of the issues involved. Her somewhat scary statement is that often, it’s nearly impossible to tell if a firestop assembly has been done wrong without doing destructive testing. As we said earlier, however, one size does NOT fit all, and there are more possibilities for error when installing the more complicated assemblies required for plastic pipes.

A final note of gratitude to everyone involved with this event. We so appreciate your partnership!