Piping Options

Millions of piping systems across North America bring clean water to families, schoolchildren, doctors/patients, and workers. They also carry away sewage and other waste, among other essential functions.

Materials play a significant role in how such systems perform. As communities initiate historic investments in piping infrastructure, they must ensure health and safety while addressing sustainability and environmental concerns. Here are key factors for each of the main types of piping.

Piping Materials

Copper

Copper has been used for centuries in plumbing and is valued for its proven resilience and non-toxic composition. Safety of copper and brass pipe and fittings is ensured by the Lead and Copper Rule to prevent leaching of harmful lead particles into piping systems.

Key applications: Water service lines, hot & cold water distribution, (steam/water) heating

Benefits: high recycled content, non-combustible, resilient to chemicals, impermeable, repairable, no leaching concerns, 75-year product life, recycled at end of life

Drawbacks: heavier weight, higher material, and installation cost

Iron

Cast iron is considered one of the most robust and forgiving materials for wastewater and sewer, selected for use in thousands of commercial and residential structures because of its safety and performance.

Key applications: Wastewater drain lines, soil pipe/sewer lines, (steam/water) heating

Benefits: high recycled content, structural strength, simple below-ground installation, resilient to chemicals, non-combustible, repairable, impermeable, no leaching concerns, 100-year product life, recycled at end of life

Drawbacks: heavier weight, higher material, and installation cost

Lead

Lead pipes were widely used for decades, but create serious health hazards due to the leaching of lead particles into water.

Well-known incidents in Flint MI, Newark NJ, and elsewhere have made it imperative to replace these unsafe pipes, work that continues in hundreds of communities.

Key applications: Water service lines, hot & cold water distribution, (steam/water) heating

Benefits: None (outweighed by risks)

Drawbacks: toxic leaching of lead into water, heavier weight

Steel

Like iron, steel is valued for its structural strength and proven performance. Steel pipes offer a high level of protection in fire incidents due to their non-combustible nature.

Key applications: Sprinkler systems, electrical conduits

Benefits: high recycled content, non-combustible, resilient to chemicals, repairable, long product life, recycled at end of life

Drawbacks: heavier weight, higher material, and installation cost

PVC

Various formulations of plastic pipe have become dominant in many segments of the market, due primarily to their cheaper material cost and low effort required to install.

Key applications: Water lines (PE, PEX, PVC), wastewater/sewer (CPVC, PVC), sprinkler systems (CPVC)

Benefits: low cost, lighter weight, versatility, cheaper to replace than repair(?)

Drawbacks: fossil-fuel content, combustible (toxic smoke & chemicals), chemical leaching in water systems, damaged by exposure to UV/chemicals/other plastics, higher permeability to pollutants, 25-year product life, landfilled at end-of-life

PE

Various formulations of plastic pipe have become dominant in many segments of the market, due primarily to their cheaper material cost and low effort required to install.

Key applications: Water lines (PE, PEX, PVC), wastewater/sewer (CPVC, PVC), sprinkler systems (CPVC)

Benefits: low cost, lighter weight, versatility, cheaper to replace than repair(?)

Drawbacks: fossil-fuel content, combustible (toxic smoke & chemicals), chemical leaching in water systems, damaged by exposure to UV/chemicals/other plastics, higher permeability to pollutants, 25-year product life, landfilled at end-of-life

PEX

Various formulations of plastic pipe have become dominant in many segments of the market, due primarily to their cheaper material cost and low effort required to install.

Key applications: Water lines (PE, PEX, PVC), wastewater/sewer (CPVC, PVC), sprinkler systems (CPVC)

Benefits: low cost, lighter weight, versatility, cheaper to replace than repair(?)

Drawbacks: fossil-fuel content, combustible (toxic smoke & chemicals), chemical leaching in water systems, damaged by exposure to UV/chemicals/other plastics, higher permeability to pollutants, 25-year product life, landfilled at end-of-life

ABS

Various formulations of plastic pipe have become dominant in many segments of the market, due primarily to their cheaper material cost and low effort required to install.

Key applications: Water lines (PE, PEX, PVC), wastewater/sewer (CPVC, PVC), sprinkler systems (CPVC)

Benefits: low cost, lighter weight, versatility, cheaper to replace than repair(?)

Drawbacks: fossil-fuel content, combustible (toxic smoke & chemicals), chemical leaching in water systems, damaged by exposure to UV/chemicals/other plastics, higher permeability to pollutants, 25-year product life, landfilled at end-of-life

Galvanized

Various formulations of plastic pipe have become dominant in many segments of the market, due primarily to their cheaper material cost and low effort required to install.

Key applications: Water lines (PE, PEX, PVC), wastewater/sewer (CPVC, PVC), sprinkler systems (CPVC)

Benefits: low cost, lighter weight, versatility, cheaper to replace than repair(?)

Drawbacks: fossil-fuel content, combustible (toxic smoke & chemicals), chemical leaching in water systems, damaged by exposure to UV/chemicals/other plastics, higher permeability to pollutants, 25-year product life, landfilled at end-of-life

Pipe System Applications

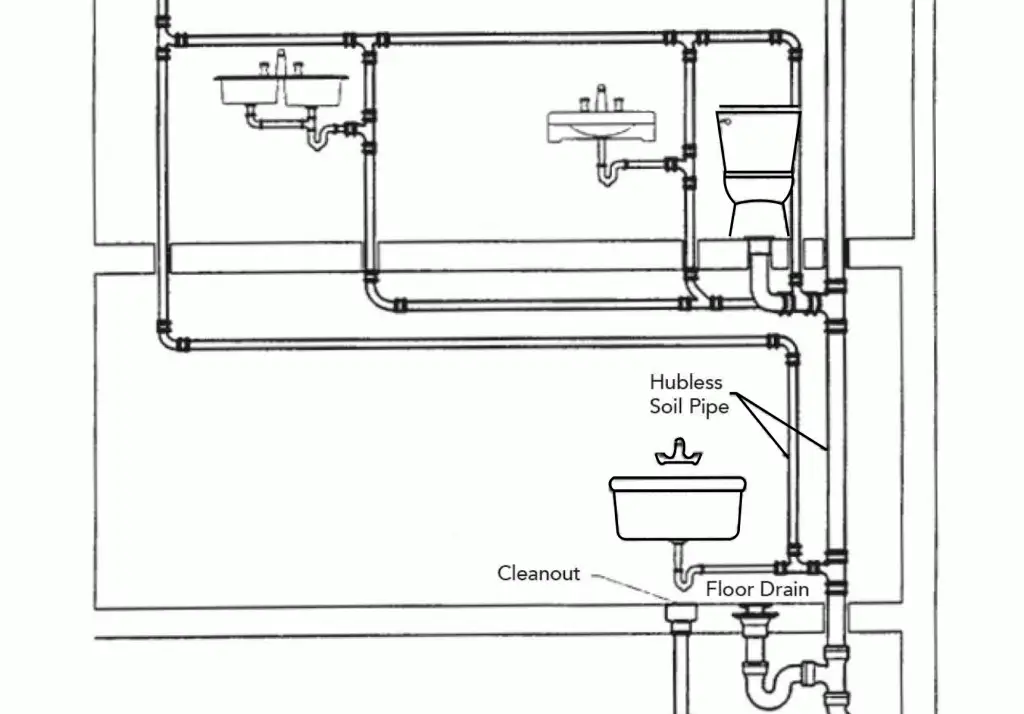

Drain, Waste & Vent Systems

Plumbing designed to move wastewater, sewage, and associated gases out of a building. DWV systems include physical drain mechanisms, piping, traps, and fittings throughout the structure, as well as sewer lines that return waste back to a municipal or septic system for treatment.

Vent pipes complement drain/waste systems by allowing mixtures of liquid and solid waste to flow easily down pipes while preventing siphonage and backflows. Vents also carry away gases and fumes associated with waste, allowing them to pass out of a structure to safeguard interior air quality.

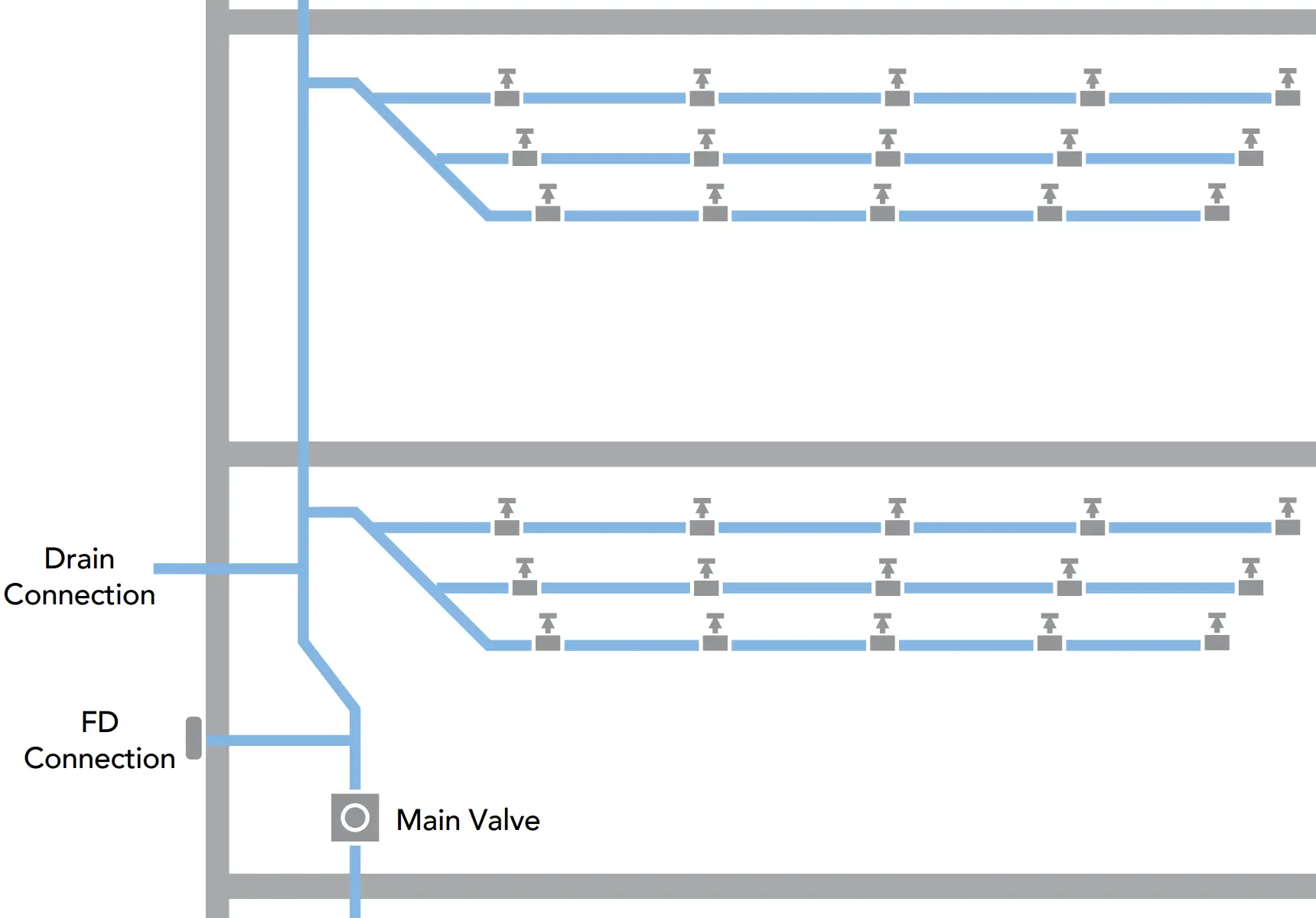

Fire Sprinkler Systems

Sprinkler systems protect occupant safety and limit property damage during structural fires. Fire-sprinkler systems can deliver water for suppression of flames, usually controlled by sensors in the protected space.

The main types of systems – wet, dry, preaction, and deluge – vary in how they are triggered, but are generally similar in construction, featuring a network of pipes and control valves located in the ceiling plenum, with sprinkler heads and sensors located below the ceiling plane.

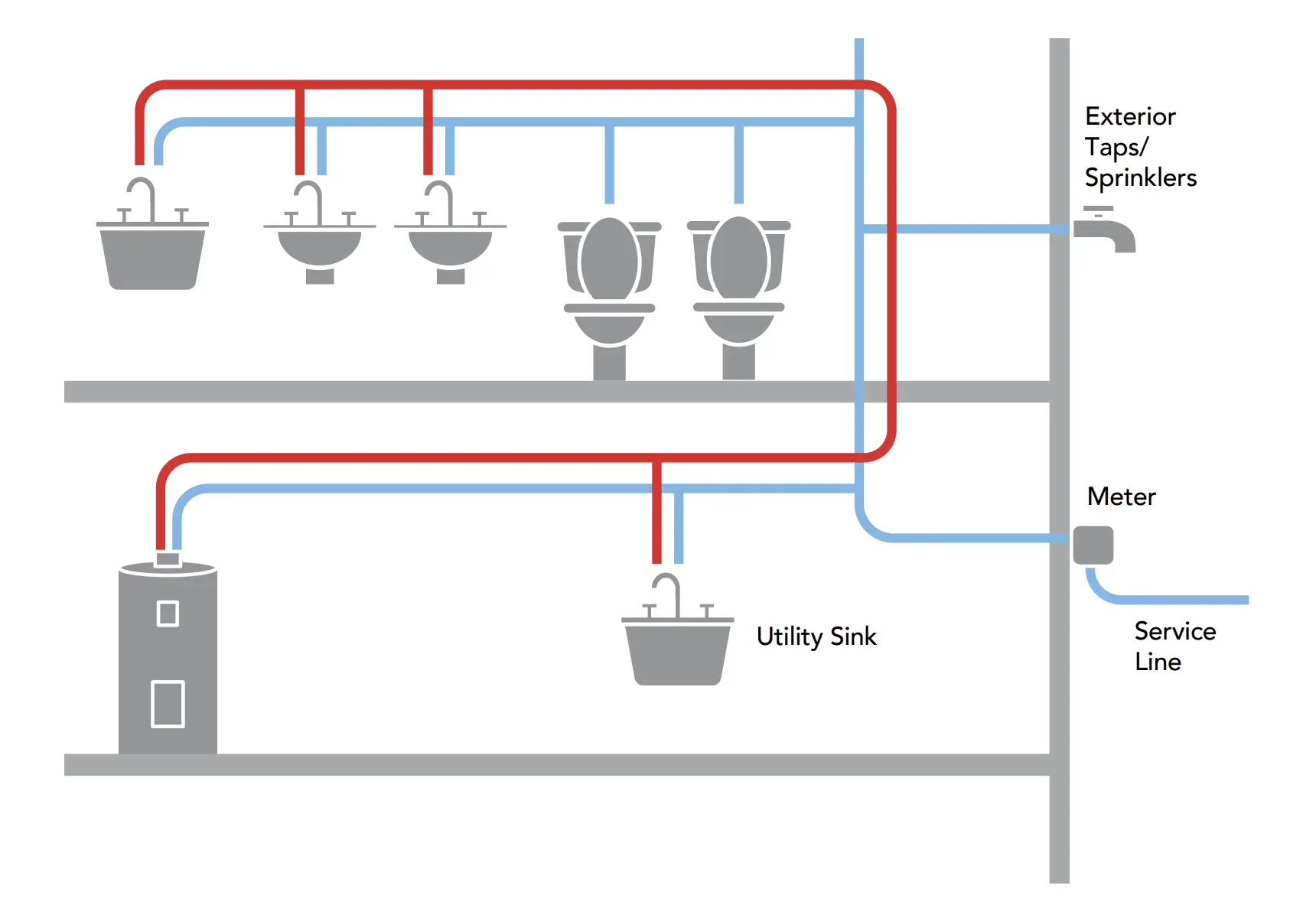

Potable Water Distribution

Potable systems supply water for drinking, washing, sanitary use, and appliances. One of the most critical parts of these systems are the pipes that connect buildings to community water sources, whether private systems or municipal supplies. Water systems then distribute water throughout a structure via a system of vertical “riser” pipes that pass from floor to floor in a structure and horizontal runs that connect individual fixtures to the water supply.

Water heaters and storage tanks are also a part of this system, as are control valves, faucets, and other fixtures.

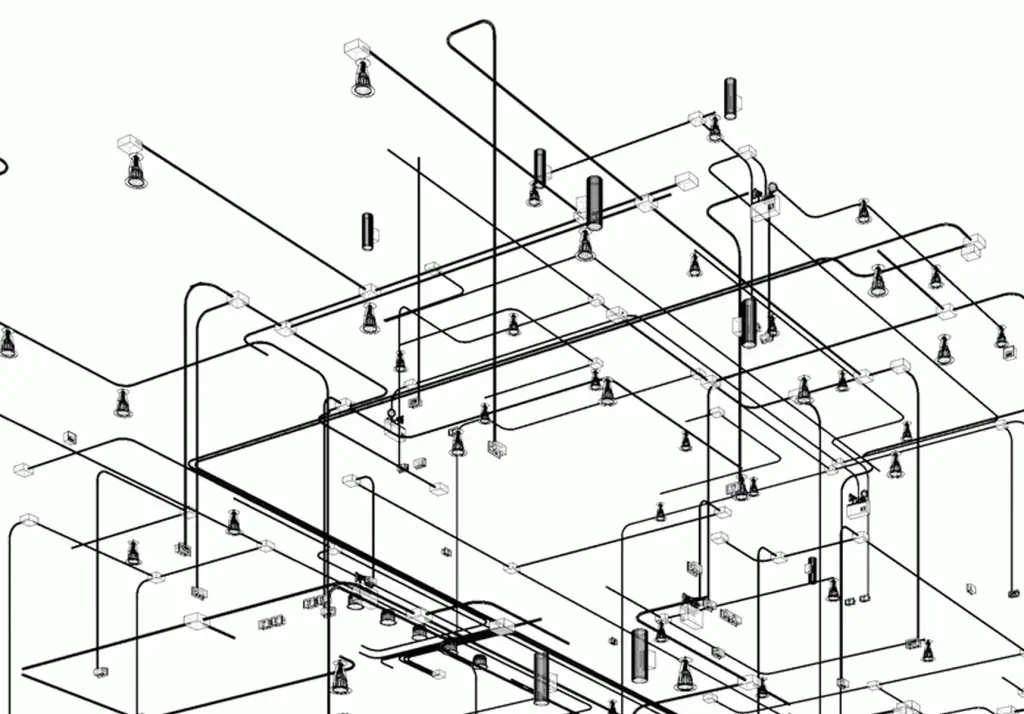

Conduit, HVAC & Other

There are many additional types of pipe systems in buildings, including electrical conduit, heating and/or cooling systems, medical gas distribution systems, and others. We do not focus on these systems today, but may add them in the future.

Additional Resources

Health & Research

- Healthy Building Network: analysis of chemicals, polymers, metals, and other substances used in construction more >

- Healthy Materials Lab: resources for designers and architects to eliminate toxic materials in the built environment more >

- Center for Plumbing Safety: Collaborative of microbiologists, risk assessors, data scientists, engineers, ecologists, and political scientists researching issues related to pipe and plumbing systems more >