Overview

Plumbing systems are essential to the safe, efficient, and sustainable operation of buildings. They enable critical subsystems like potable water delivery, sanitation, and fire suppression, core functions that directly impact operational resilience, human health, and long-term building value. Plumbing materials must do more than meet code. They must support broader goals for indoor environmental quality (IEQ), water conservation, and occupant well-being.From a systems perspective, pipe materials influence not only mechanical durability but also chemical stability. Pipes that degrade over time or interact negatively with water can introduce contaminants into drinking-water systems, undermining occupant trust and triggering maintenance and liability concerns. Design and building teams who seek alignment with LEED v4.1, WELL Building Standard, or Materials Petal certification cannot overlook plumbing as an opportunity to specify healthier, more sustainable materials.

Plumbing systems are essential to the safe, efficient, and sustainable operation of buildings. They enable critical subsystems like potable water delivery, sanitation, and fire suppression, core functions that directly impact operational resilience, human health, and long-term building value. Plumbing materials must do more than meet code. They must support broader goals for indoor environmental quality (IEQ), water conservation, and occupant well-being.From a systems perspective, pipe materials influence not only mechanical durability but also chemical stability. Pipes that degrade over time or interact negatively with water can introduce contaminants into drinking-water systems, undermining occupant trust and triggering maintenance and liability concerns. Design and building teams who seek alignment with LEED v4.1, WELL Building Standard, or Materials Petal certification cannot overlook plumbing as an opportunity to specify healthier, more sustainable materials.

Despite their long service life and proximity to drinking water, plumbing materials are often selected without thorough evaluation of their chemical safety, environmental impact, or health implications. Standard practice too often defaults to cost-driven choices or contractor familiarity, with little scrutiny of a material’s performance over decades of exposure to varying water chemistry, temperature, and pressure. In value-engineered projects, materials may be substituted late in the process with little consideration of toxicity, leaching behavior, or recyclability.

Despite their long service life and proximity to drinking water, plumbing materials are often selected without thorough evaluation of their chemical safety, environmental impact, or health implications. Standard practice too often defaults to cost-driven choices or contractor familiarity, with little scrutiny of a material’s performance over decades of exposure to varying water chemistry, temperature, and pressure. In value-engineered projects, materials may be substituted late in the process with little consideration of toxicity, leaching behavior, or recyclability.

This oversight can have long-term consequences – especially in sensitive building types such as hospitals, schools, or multifamily housing. Poorly chosen pipe materials may introduce chemical contaminants into water supplies and suffer material degradation when exposed to common potable-water disinfectants such as chloramines. From a sustainability perspective, teams that fail to consider chemical migration and health effects may come into conflict with transparency goals including Health Product Declarations and Red List compliance. They also undermine the intent of high-performance design.

Leaching: A Hidden Risk in Pipe Selection

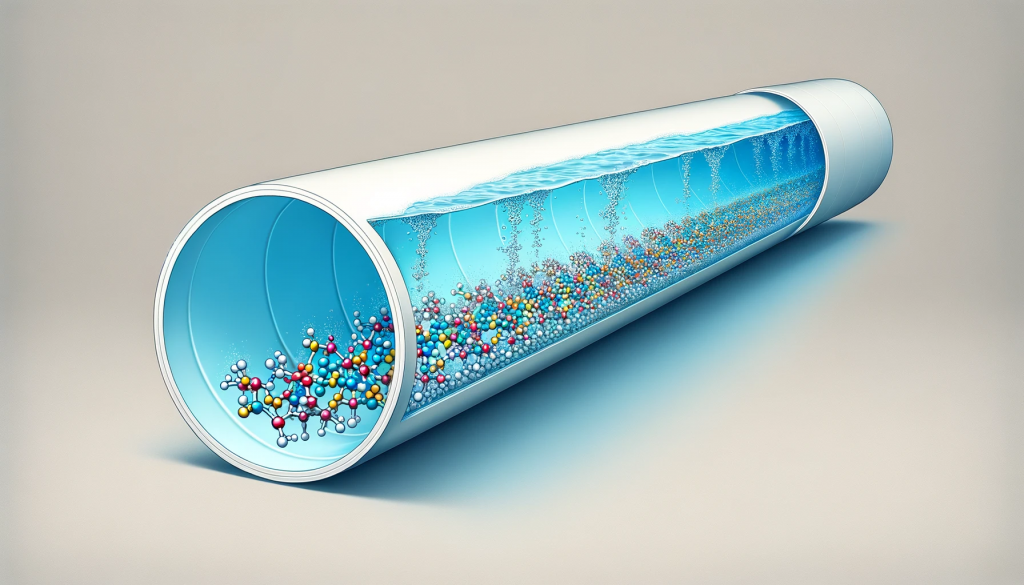

In a plumbing system, leaching is a process by which substances from the wall of a pipe migrate into whatever flows through that system. These “leachates” can include many substances that have negative or unknown health impacts.

In a plumbing system, leaching is a process by which substances from the wall of a pipe migrate into whatever flows through that system. These “leachates” can include many substances that have negative or unknown health impacts.

Leachates from pipes fall into two general categories:

- Chemicals including plasticizers, VOCs, dyes, and other proprietary additives from the manufacturing process

- Physical fragments of the pipe. Examples include

- Molecules shed from benign metals such as copper and iron

- Microplastic and nanoplastic particles, which have health impacts that are not fully understood, and

- Toxic lead particles and heavy metals

Factors such as water chemistry, temperature, stagnation time, and system age all influence leaching processes. Some of the most influential factors, however, relate to the chemical composition and molecular stability of the pipe material. Some materials – especially plastics comprised of petrochemicals – are more sensitive than others.

Leaching presents direct risks to human health when ingested, such as toxins, carcinogens, and chemicals that disrupt endocrine function and reproductive health. Leaching can also cause other issues related to water quality degradation, encouraging microbial growth or affecting the taste and odor of water. More troubling is the fact that the long-term health impacts of exposure to many leached substances are still under investigation, so the risks are unknown.

Leaching presents direct risks to human health when ingested, such as toxins, carcinogens, and chemicals that disrupt endocrine function and reproductive health. Leaching can also cause other issues related to water quality degradation, encouraging microbial growth or affecting the taste and odor of water. More troubling is the fact that the long-term health impacts of exposure to many leached substances are still under investigation, so the risks are unknown.

Standards such as NSF/ANSI 61 attempt to set safety thresholds, but these are based on limited compound lists and short-term test conditions. Real-world exposures can differ significantly, particularly in systems with long stagnation times or elevated temperatures (e.g., hot water recirculation or fire sprinkler systems). These exposures are particularly concerning for vulnerable populations such as children, pregnant individuals, or immuno-compromised occupants.

Standards such as NSF/ANSI 61 attempt to set safety thresholds, but these are based on limited compound lists and short-term test conditions. Real-world exposures can differ significantly, particularly in systems with long stagnation times or elevated temperatures (e.g., hot water recirculation or fire sprinkler systems). These exposures are particularly concerning for vulnerable populations such as children, pregnant individuals, or immuno-compromised occupants.

Materials that leach harmful substances undermine goals related to clean water access, non-toxic environments, and product transparency. Furthermore, they may lead to increased system flushing, filter use, or even premature replacement, all of which increase the building’s environmental footprint over time. In the larger context of whole-building life cycle assessments (LCAs), materials that require active mitigation or are incompatible with circular economy principles (e.g., reuse, recycling) are inherently less sustainable. In short, leaching stands at a critical intersection of health, materials science, and sustainability, and should be a central consideration in the selection of plumbing materials.

Leaching is most relevant in drinking water distribution systems, where pipes are in constant contact with water that may be consumed by occupants. It also merits attention in fire protection systems, however, especially those using standing water in non-recirculating systems, as stagnation can increase chemical migration. While drain-waste-vent (DWV) systems typically do not involve water reuse, leaching from pipes into graywater or infiltration into surrounding materials can still contribute to indoor environmental exposures or system incompatibilities.

Leaching is most relevant in drinking water distribution systems, where pipes are in constant contact with water that may be consumed by occupants. It also merits attention in fire protection systems, however, especially those using standing water in non-recirculating systems, as stagnation can increase chemical migration. While drain-waste-vent (DWV) systems typically do not involve water reuse, leaching from pipes into graywater or infiltration into surrounding materials can still contribute to indoor environmental exposures or system incompatibilities.

Leaching Risks of Pipe Materials

While all piping materials can introduce some level of contamination, the scale, type, and risks from leached substances vary significantly depending on the base material. In particular, multiple studies demonstrate that plastic pipes – including PVC, CPVC, PEX, PE, ABS, and HDPE – leach a wide variety of organic compounds. These include plasticizers, residual solvents, unreacted monomers, antioxidants, UV stabilizers, halogenated compounds, organotins, and endocrine-disrupting chemicals. Many of these substances are either unregulated or lack robust health data, a critical gap in safety and health standards such as NSF/ANSI 61, “Drinking Water System Components – Health Effects,” which establishes minimum requirements for pipes and fittings.

By contrast, metal pipes like copper, cast iron, and steel have better-defined compositions and produce a limited range of corrosion byproducts. Copper pipes, for example, may leach small amounts of cupric ions, an essential nutrient for muscle and heart function. The regulatory limit for copper is 1,300 ppb. Iron pipes may leach oxidized metal particles (rust), which the body can use to support both the immune system and blood. Iron is considered a secondary contaminant primarily because at higher levels (in excess of 300 ppb) it can affect the taste, odor, and color of water. The exception for metal materials is lead, a leachate that can have negative health impacts at any level, and whose regulatory limit is far lower than copper or iron at 15 ppb.

Plastic Pipes Leach Chemicals & Microplastics | Metal Pipes Leach Copper & Iron Particles |

|  |

Pipe Material Health & Safety Rankings

This scorecard ranks common plumbing materials according to the amount, toxicity, and regulatory uncertainty of chemicals leached into drinking water, as documented in peer-reviewed studies, standards assessments, and environmental health reviews. Note that this ranking excludes obsolete materials such as lead pipes (known to be toxic) and polybutylene plastic pipes (no longer used in the U.S. due to extensive failures).

This scorecard ranks common plumbing materials according to the amount, toxicity, and regulatory uncertainty of chemicals leached into drinking water, as documented in peer-reviewed studies, standards assessments, and environmental health reviews. Note that this ranking excludes obsolete materials such as lead pipes (known to be toxic) and polybutylene plastic pipes (no longer used in the U.S. due to extensive failures).

Ranking

1. Cast Iron – Ranking: Very Low Risk Cast iron has no known leaching of organic chemicals. Pipes are inert under most water conditions; primary risk is iron bacteria or aesthetic staining, not human health. Primarily used in DWV systems. Approved for potable use when lined.

|  |

2. Steel (Galvanized or Stainless) – Ranking: Low Risk Leaching limited to minor zinc or iron ions; generally minimal in lined or stainless steel variants. Galvanized steel may leach trace metals like lead or cadmium from older fittings or solder joints, not the steel itself.

|  |

3. Copper – Ranking: Low Risk to Moderate Risk Leaches cupric ions, especially under low pH or soft water conditions. Copper leachates are well studied and regulated (e.g., EPA Action Level = 1.3 mg/L). Risk is relatively low and declines with system age. May need corrosion control in aggressive water conditions. Copper systems with soldered or brazed joints may pose a small risk of lead exposure if older, non-lead-free materials were used. |  |

4. PE / HDPE – Ranking: High Risk Known to leach alkyl phenols, quinones, antioxidants, and degradation products. Composition varies widely by manufacturer; multiple studies note migration of unknown or unregulated chemicals. Moderate thermal resistance, but elevated temps accelerate leaching. |  |

5. PEX – Ranking: High to Very High Risk Among the most chemically active plastics in drinking water systems. Known to leach VOCs (e.g., MTBE, toluene), bisphenol analogs, phthalates, and manufacturing residues. Leaching highest during first year and after stagnation or heating; issues persist for years in some studies. |  |

6. PVC – Ranking: Very High Risk Leaches halogenated organics, vinyl chloride monomers, phthalates, and organotins. Major source of unregulated leachates: ~74 substances identified with no health standards. Risk of extreme contamination during thermal degradation (e.g., damage from overheating or fires). |  |

7. CPVC – Ranking: Very High Risk Similar leaching profile to PVC, but often used in hot water systems, increasing volatility and chemical migration. Documented leachates include chlorinated VOCs, organotins, and phthalates. Also vulnerable to solvent cement degradation and microbial colonization. |  |

8. ABS – Ranking: Very High Risk Known to leach styrene (a potential human carcinogen), along with VOCs and additives. Not typically used for potable systems but sometimes installed inappropriately. Poor thermal and chemical stability relative to other polymers. |  |

Recommendations

All AEC professionals should follow a few fundamental steps when designing and installing plumbing systems:

All AEC professionals should follow a few fundamental steps when designing and installing plumbing systems:

- Discuss plumbing system design early on in a project to align with each client’s material goals. How do building safety and occupant health rank compared with costs and other considerations?

- Weigh the toxicity, chemical stability, and end-of-life impacts of the plumbing materials specified and/or installed on a project.

- Review product data sheets and/or Health Product Declarations (HPDs) for piping materials, looking for Red List and other problematic substances. If safety and health documentation is unavailable or incomplete (common for plastics), consider this a red flag.

In addition, each of the major groups responsible for building plumbing – architects, engineers, and construction professionals – should incorporate the following guidance into their specification and design processes.

Guidance for Architects

- Prioritize low-leaching materials in all potable water systems, particularly in schools, healthcare, and residential projects where sensitive populations are present. Favor cast iron, copper, or stainless steel in specifications over plastic piping materials.

- When pursuing health-focused certifications like WELL, Living Building Challenge, or LEED v4.1 (MR credits), consider excluding PVC, CPVC, PEX, and ABS from drinking water systems due to their association with unregulated or endocrine-disrupting chemical leachates.

- Include chemical safety and material health criteria in Division 22 and 33 product selection standards. Require third-party certifications like NSF/ANSI 61 and review whether they reflect real-world usage scenarios.

Guidance for Mechanical & Plumbing Engineers

- Design with chemical compatibility and water chemistry in mind. If specifying copper, evaluate corrosion control measures to reduce leaching under acidic or low-alkalinity conditions.

- For fire suppression or antifreeze-based systems, avoid CPVC and PEX where water stagnation or elevated temperatures are expected, due to increased risk of leaching.

Guidance for Contractors & Installers

- Be aware that value-engineered substitutions from metal to plastic may introduce chemical exposure risks, especially in hot or stagnant water systems.

- Avoid using solder with any lead content when installing copper systems. Confirm that fluxes, fittings, and brazing rods are lead-free and NSF-compliant.

- Where plastic pipe is unavoidable, take steps to flush systems extensively before putting them into service and document this process. Inform building operators of potential changes in water quality during the first year of use.

Sources

- “Addressing systemic problems with exposure assessments to protect the public’s health,” Environmental Health, Vandenberg et al., 2022.

- “Characterization of Leachable Chemical Solutions from Common Drinking Water Piping Materials,” Gradient, Daniella M. Pizzuro et al., 2019.

- “Contaminant Migration from Polymeric Pipes,” Purdue Univ., A. Whelton et al., 2013.

- “Drinking Water Contamination from the Thermal Degradation of Plastics,” Environmental Science: Water Research & Technology, Andrew Whelton et al., 2020.

- “Endocrine Disruptors & Obesity,” Current Obesity Reports, Philippa D. Darbre, Mar. 2017.

- “Halogenated Hydrocarbon,” Encyclopedia of Ecology, M.A.Q. Khan et al., 2008.

- “Iron in Drinking Water,” Bureau of Drinking Water & Groundwater, Wisconsin Department of Natural Resources, 2001.

- “Leachable Volatile Organic Compounds from Polyethylene Plumbing Plastic Pipes,” ACMY, Muhammad Mansoor Shaikh et al., 2017.

- “Lead in Drinking Water from Plumbing Components,” U.S. Environmental Protection Agency (EPA), Feb. 2022.

- “Material Considerations for Plumbing Systems” (presentation), SafePipingMatters.org, updated 2025.

- “NSF/ANSI Standard 61: Drinking Water System Components—Health Effects,” NSF International, 2016.

- “Organotin Exposure and Vertebrate Reproduction: A Review,” Frontiers in Endocrinology, Julia Fernandez Punal de Araujo et al., Mar. 1, 2018.

- “Perils of PVC Plastic Pipes,” BeyondPlastics.org, Meg Wilcox, 2023.

- “Plastics Scorecard v1.0,” Mark Rossi & Beverley Thorpe, Mar. 2015.

- “Potable Water Piping Guidance,” HabitableFuture.com, Habitable, Apr. 25, 2023.

- “Project TENDR: Targeting Environmental Neuro-Developmental Risks,” Environmental Health Perspectives, TENDR., July 2016.

- “Red List Building Product Watchlist,” International Living Future Institute, ILFI Red List Guide, 2023.

- “Scientists Raise Questions About How PEX Pipes Affect Water,” Water Online, Sara Jerome, June 16, 2016.

- “Specifying Piping Materials for Water Infrastructure Systems,” Environmental Science & Engineering Magazine, Daniella M. Pizzurro, David Mayfield & Ifeoluwa A. Bamgbose, June 4, 2018.

- “Water Service Lines,” CDA, copper.org/applications/plumbing/water_service, accessed Aug. 10, 2025.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.