Building Evolution – A Look at Materials, Part 2: Issues and Alternatives

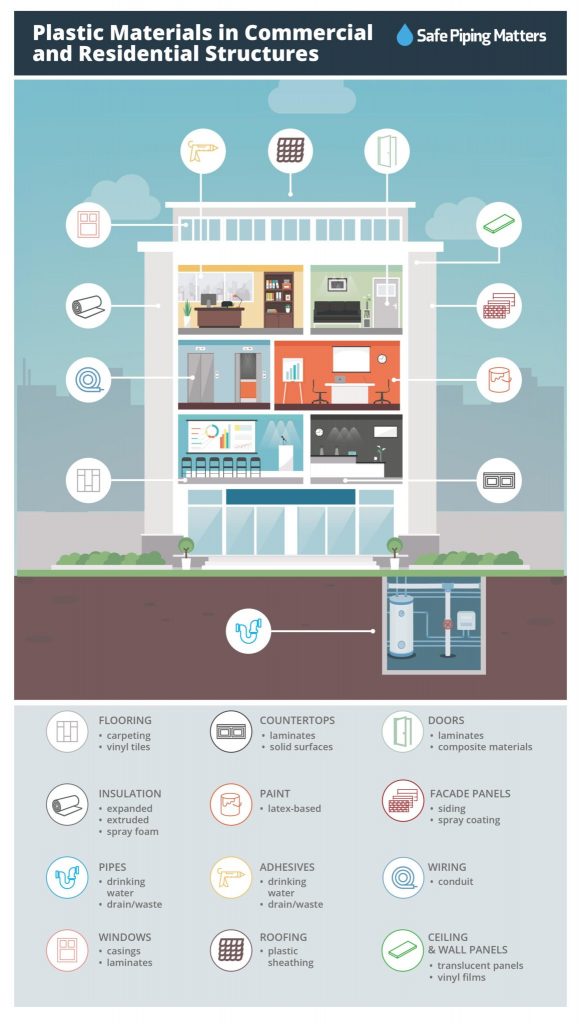

In our previous post, we discussed the risks associated with increased use of plastics for construction and interior furnishings. The adjacent diagram shows where plastic materials commonly appear in low-rise and multi-story commercial and multi-unit residential structures. (Click the image to view at full size.)

Proven alternatives exist for nearly all these applications. And while none is perfect, many of these offer significant benefits in terms of initial environmental impact, human health and safety during use, and the ability to reuse and recycle at the end of product lifecycle. The list below – inspired by Building Green’s Spec This Not That, Avoiding Toxic Chemicals in Commercial Building Products – shows three key examples of applications, key issues and alternatives to consider.

Flooring

Plastic Issues

- Low/no recycled content

- High VOC emissions degrade interior air quality

- May contain PFAs, antimicrobial, and other toxins

Alternatives to Consider

- Products from manufacturers with takeback programs

- PVC-free flooring

- FSC, reclaimed, and green-certified wood

Piping

Plastic Issues

- Can melt or burn, compromising firestopping and fueling flame spread

- Chemical leaching into water

Alternatives to Consider

- Copper

- Ductile iron

- Steel

Wall & Ceiling Panels

Plastic Issues

- Emit toxic smoke

- Burn hotter

- Contain low/no recycled content

Alternatives to Consider

- Aluminum

- Wood

One thing is clear: as the design and construction industry learns more about the true cost of using plastic materials, growth in use of plastics will not continue. By contrast, it’s very likely to decrease significantly as architects, engineers, and builders increasingly consider which products containing plastic fit the standards of performance and safety they want to incorporate in their buildings.