Value Engineering in Plumbing Systems

Introduction

Construction project teams select materials based on many factors, including durability, sustainability, safety, aesthetics, and cost, among others. When well executed, the process of value engineering (VE) can optimize this last factor – the cost of a system – while still performing all essential functions. For many architects, engineers, and owners, as well as some contractors, value engineering has a tarnished reputation, however. When VE efforts fall short, the results can be devastating, especially with building plumbing systems.

A recent example from Baltimore offers a case in point. The contractors responsible for building a harborside hotel – Hensel Phelps Construction and Southland Industries – “value-engineered” building plumbing systems by substituting a lesser material in place of what architects had specified. The pipes failed within 7 years, turning the $2.6 million contractors “saved” into a legal liability they reportedly settled at a cost of over $18 million.

In a recent discussion with a number of plumbing professionals, one of them made the following observation about value engineering of plumbing systems: “Most value engineering efforts deliver very little value and no engineering.”

That seems like the case for that ill-fated project in Baltimore, but it’s not true universally. Many architects and engineers work closely with contractors to strike the right balance of cost with other factors. This report takes a comprehensive look at VE issues specific to plumbing systems. What issues should design and construction professionals consider? And what steps should they take to avoid over-prioritizing cost at the expense of plumbing system integrity?

Overview

Plumbing systems in buildings generally support the following functions:

- Supply and distribution of potable water for drinking, washing, sanitary use, and appliances.

- Drain, waste, and ventilation (DWV) to remove wastewater, sewage, and associated gases.

- Fire-sprinkler systems that protect occupant safety and limit property damage.

Some buildings also include piping for heating or other systems, but this report will not review these or other less common applications. The piping materials predominantly used for water, DWV, and fire-sprinkler systems include copper, cast-iron, and a number of plastics, including polyvinyl chloride (PVC), cross-linked polyethylene (PEX), and polyethylene (PE). This report focuses mainly on these materials but will also refer to obsolete plumbing materials. Such problematic pipes include failed polybutylene plastic pipes, toxic lead pipes, and galvanized steel pipes. These materials offer valuable lessons on the significant consequences of plumbing problems.

Challenges and Risks

When designing, specifying, and installing plumbing systems, project teams should review a number of issues that are critical to building safety and performance. They must also consider the type, size, and location of the building when specifying the required level of performance for each of these factors. This report examines several of the most important of these for plumbing systems, including the following.

Plumbing System Considerations

Safety: How well does the plumbing maintain the integrity of protective measures in buildings?

Durability: What factors affect how long the system will perform to the standards that are required?

Resilience: What other factors may threaten the integrity and performance of the plumbing?

Health: Will the system protect occupants from illness and exposure to substances with negative impacts on wellness?

Sustainability: How great an impact does manufacturing, operating, and removing a system have on the environment?

Insurance liability: What are insurers finding with regard to losses related to building plumbing?

Other factors

Fire Risk Considerations for Value Engineering

Architects and construction teams work hard to increase fire safety in the buildings they create. Building codes set standards intended to limit risks and to protect occupants and first responders. Research shows that materials also matter when it comes to structure fires. For plumbing systems, the issues center on combustibility and toxicity.

Fire Resistance and Safety Issues

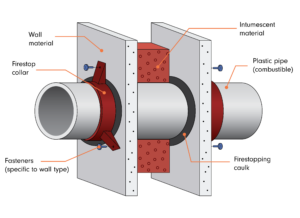

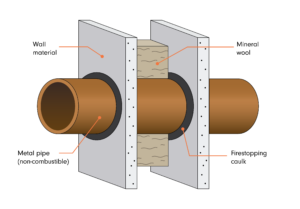

Many plumbing systems pass through walls and ceilings, penetrating barriers that otherwise would slow the spread of flames and smoke in the event of a fire. Codes require construction teams to take measures that will impede movement of a fire from room to room or between floors, but the complexity of such measures is significantly different for copper and iron pipes than those required for PVC, CPVC, PEX, PE and other plastic pipe materials.

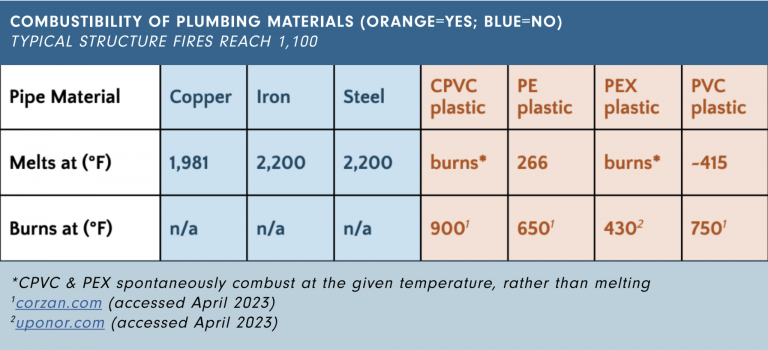

That’s because during fires, the petroleum-based compounds in plastic pipes are combustible. They represent a fuel source for smoke and flames. Chart 1 shows melting and combustion temperatures for commonly used plumbing materials. A typical structural fire will average 1,100 degrees, according to The Fundamentals of Fire Protection.

Toxic Smoke and Deadly Flame Spread

Plastic materials pose a further fire risk factor for building owners and construction teams to consider: the smoke and fumes produced during a fire. Chemical analysis of plumbing assembly fire tests show plastic materials produce thicker and more toxic smoke. In less than 15 minutes, the burning pipes generated high levels of hydrogen chloride (HCl), hydrogen cyanide (HCN), sulphur dioxide (SO2), hydrogen fluoride (HF), hydrogen bromide (HBr), carbon dioxide (CO2), carbon monoxide (CO), nitrogen oxide (NOx), and nitrogen dioxide (NO2).

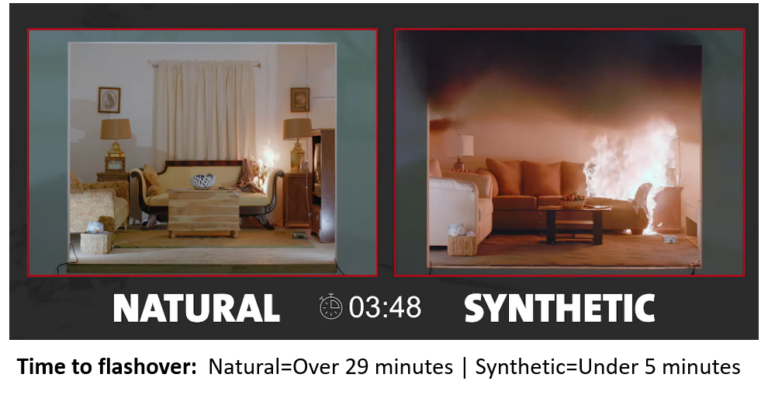

As important, tests completed by the Fire Safety Research Institute shows that fires in structures with higher levels of plastic burn hotter and more quickly. This screenshot from their compelling video shows how fires progressed in two different rooms. The room on the left was designed with materials like wood, metal, cotton, and wool. The one on the right was designed with plastic laminates, cushions containing plastic foam, and polyester-type fabrics. Despite the use of flame-retardant additives, the room containing synthetics was fully engulfed in less than 5 minutes. This rapid acceleration leaves any occupants very little time to escape and firefighters virtually no time to respond. By contrast the room with natural materials lasted more than 29 minutes before it was fully burning.

Flashover Test Results

A fire at the MGM Grand hotel and casino in Las Vegas marked a turning point in safety standards for building design and construction. The fire killed 85 and injured another 679 when firestops and fire barriers penetrated by PVC piping failed. Accounts of this incident describe a wall of flames and report that it took just six minutes for the entire casino floor to be fully engulfed.

Since then, building systems and practices have continued to evolve but the following principles remain essential considerations for ensuring safety:

- To minimize fire risks, keep mitigation methods and firestopping assemblies as simple as possible. Systems with fewer and less complex components will reduce the number of errors that compromise safety.

- Consider reducing the use of materials using combustible petrochemicals, giving occupants more time to escape and exposing them to lower levels of toxic smoke, gases, and soot.

- If combustible plumbing materials are used, ensure that they pass unmodified smoke and flame tests. Workarounds in a test configuration may not function in a real-world fire.

Durability and Resilience Considerations for Value Engineering

Building teams must also consider the structural strength of pipe materials, which affects how they are configured, installed, and protected. Furthermore, plumbing systems must withstand wear and tear from a variety of sources during use, resisting damage from physical, chemical, and environmental stresses. Properly installed and maintained pipes should last the lifetime of a building.

Pipe Issues Below Grade

Plumbing systems buried underground pose special challenges and should not be considered for value engineering without careful consideration. Buried pipe must withstand many stresses, including pressure, vibrations, shifts in the building/substrate, and exposure to substances both inside and outside the pipe. Furthermore, buried pipes can often prove difficult to inspect, repair, and replace, raising the stakes for trouble-free performance.

Deflection is one significant issue engineering should consider. This issue may occur when the weight of material above a plumbing system – such as soil, building material, and equipment – compresses the pipe into an ovoid shape. Over time, the resulting mechanical stresses can cause cracking/crushing and lead to small leaks or even full breaks. Variations in soil composition along the pipe run – such as changes from more compacted to less compacted material – can cause similar issues. Many installation processes recommend or require backfilling with a homogeneous material such as sand or gravel.

- Cast-iron pipe can be laid in a trench nearly the same width as the pipe itself because it is not subject to deflection. Iron pipe could still fail by crushing if overloaded with weight from above, however.

- Copper pipe may be installed directly into a trench as this material is “naturally corrosion-resistant to most soils and underground environments.” If local jurisdictions require wrapping, installers should ensure the membrane is undamaged to minimize exposure to corrosive substances.

- CPVC resists exposure to chlorine but installers must ensure it does not come into contact with certain types of vinyl. Flexible materials like vinyl sheeting that might be okay to use with metal pipe contain plasticizers that “will migrate” to the CPVC and damage it.

- PEX pipes may not be recommended for underground applications, so installers must consult manufacturer guidelines to ensure reliable operation. If PEX pipes are used, they must be secured in place and require support and backfilling to limit shifting that can cause issues with operation. Some applications of PEX pipe will also need insulation to be placed around the pipes. Others may require them to be installed inside a PVC pipe for protection.

- PVC plastic pipe “is considered to be in a failed condition” when deflection is above 5%, according to a leading manufacturer. Protecting plastic pipe against this issue requires trenching wider to support the plastic from both sides for stability. A specific method for supporting the pipe from below must also be installed.

Value engineering of pipes installed in sub-basements or between buildings on a campus should also consider issues related to buoyancy. Areas where high groundwater occasionally occurs create the risk that pipe will float upward in the soil, heaving pipes out of position. This problem may occur when buoyancy forces on the pipe exceed the weight of the pipe and backfill. A number of major water providers recommend ignoring the weight of the contents of a pipe, allowing for “the weight of the liquid… as an additional safety factor and the possibility of the pipeline not being in use during a period of time.” By definition, lighter, less dense pipes, including PVC, PE, and other plastics, will be more buoyant. Recommendations for mitigating the risk of pipes heaving include strapping saddle bags on top of pipes, adding concrete collars, installing anchors, increasing the thickness (weight) of the pipe material, or burying the pipe at a deeper depth.

Those reviewing the cost of plumbing in underground locations must also consider the risk of damage from corrosive reactions with the environment. Cast-iron, ductile iron, and copper pipe all have high resistance to many sources of corrosion. PVC also resists most corrosion. CPVC pipe must be protected against exposure to a wide range of chemicals, including common lubricants and cleaning products. Design teams must test soil in areas where pipes will be installed to determine what if any protective measures should be taken. Such analysis looks for factors that could damage various pipe materials. The risks vary by type – here are some examples:

- Exposure to certain oils and solvents can damage PVC pipes;

- Groundwater with high ammonia levels may damage copper pipe; and

- The presence of strong acids (below 4.3 pH) could damage cast iron.

If these or other conditions are identified, teams should specify wraps and coatings to protect the integrity of pipe materials.

Supports and Sagging Aboveground

When reviewing pipe installations in aboveground locations inside buildings – such as air plenums, crawl spaces, and utility areas – cost considerations must include the need for support. Without appropriate support, the weight of the pipe and any contents will reduce the integrity of the plumbing system, causing pipes to sag and putting strain on joints. Variations in temperature in unconditioned spaces or due to heated/cooled liquids may amplify such effects as pipes expand and contract, especially for materials like CPVC and other plastics.

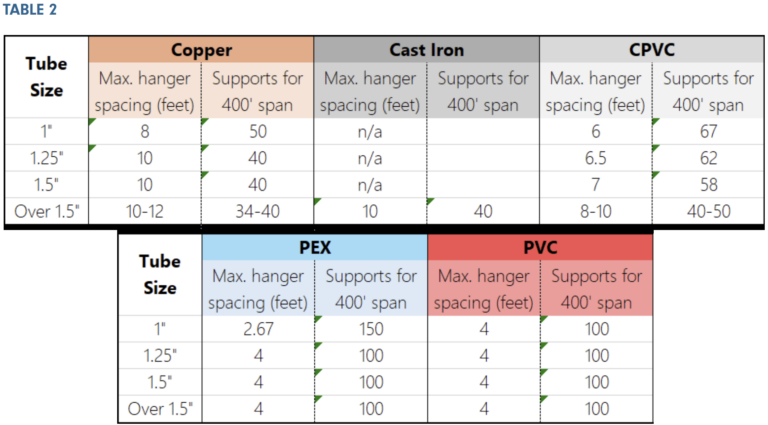

With that in mind, specifying teams must look at the total installed cost of pipe, suspension components, and installation labor when evaluating various materials. In general, costs increase in direct relationship with the number of required support points. Table 2 shows how many hangers are required for different types and sizes of pipe.

Copper: Pipes made of Type M copper have a comparatively high level of resistance to deformation under stress (AKA the modulus of elasticity). As a result, they require fewer points of support than less rigid plastic alternatives – one every 6 to 8 feet for tube sizes commonly used in buildings. The reduction in labor costs can become significant: one study comparing copper and CPVC fire-sprinkler piping demonstrated savings of 80 minutes across even a small, 500-foot run.

Cast Iron: Pipes made of iron exhibit high structural strength and are not susceptible to sagging. As a result, they require support only at joints to support pipes adequately and maintain alignment. Because 10-foot lengths are widely available, hangers may be spaced up to 10 feet apart.

CPVC: The lighter weight and lower stiffness of this material requires more support. Hangers should be installed every 3 to 4 feet, depending on the tube size. For sprinkler systems, individual supports at each discharge point may also be needed.

PEX: One of the advantages of PEX is flexibility, allowing runs that can curve with fewer elbows and joints. This characteristic increases the need for support; codes require hangers every 32 inches for smaller tubes and every 4 feet for tubes larger than 1.25 inches.

PVC: This material is among the stiffer types of plastic piping. It requires hangers every 4 feet. Drain, waste, and vent applications will need about double the number of hangers compared with cast iron.

Physical Impacts

Physical impacts represent another concern for certain plumbing applications in buildings. This is true particularly for areas where the risk of damage to pipes may be higher, such as under foundations or paving, near high-traffic areas inside buildings, on manufacturing floors, and in parking garages.

Crush load is a commonly used measure of resistance to damage, so engineers and architects should consider materials that feature higher crush values. Cast iron is the most resilient piping material. Plastic pipe with cellular cores has the lowest crush rating.

Longevity and Wear Under Various Conditions

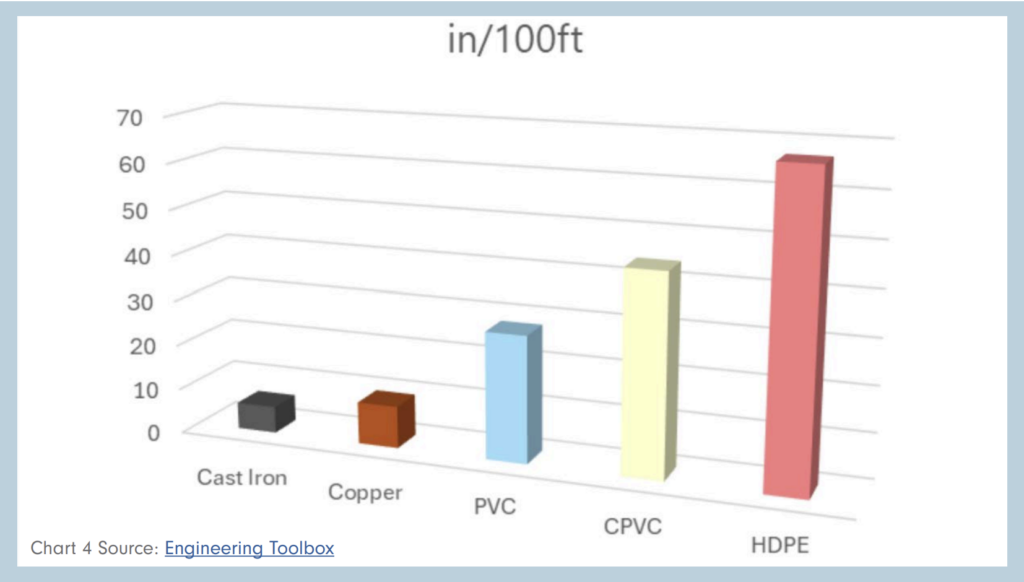

Thermal effects represent another form of stress that must be considered in value engineering. Temperature fluctuations cause expansion and contraction along pipe runs that can affect the fidelity of joints and fittings by causing them to loosen or crack. A similar principle holds for firestop brackets and fasteners.

When reviewing pipe specifications for potential substitution, architects and engineers should consider thermal effects, particularly in un-conditioned spaces like exterior walls, shafts, and soffits. All these spaces may experience significant temperature swings during a day or from summer to winter. A more stable material may be appropriate for such locations.

Chart 4 shows the relative amount of expansion for various piping materials:

Cast-iron pipes again perform best, followed by steel and copper, with PVC, CPVC, and HDPE expanding more with swings in temperature.

Chemical Incompatibilities and Other Hazards

When substituting one pipe material for another, teams must consider what hazards may affect the pipe in its installed location. Chemical compatibility problems have caused uncounted numbers of plumbing failures. Sometimes mistakes in installation cause these problems, such as in one office building where network cabling laid alongside pipes led to failures after plasticizers in the wires ate “wormholes” into the pipe walls.

Incidents can also sometimes occur as a byproduct of maintenance on other building systems, if overspray or drips of common products like mold/insect treatment, lubricants, caulk, and firestopping chemicals get onto pipes. One high-rise residential building suffered millions in water damage when CPVC fire-sprinkler pipes in a plenum space failed after being exposed to WD-40. Similar points of risk include custodial closets and areas under sinks, where harsh chemicals are often stored.

The reactivity of the pipe material relates directly to risk. Here is a brief comparison of pros and cons:

Copper: Generally impervious to corrosion though it may experience issues with water that has pH levels of 7.0 to 7.7 and dissolved CO2 of at least 25 milligrams per liter. Bringing the pH into the acceptable range will eliminate this risk. Systems that do not test and treat problems can experience pitting and pinhole leaks.

Cast iron: Even more resistant to acids than copper, with little impact until solutions fall below a pH of 4.3. Codes and standards require a special waste system piping for highly acidic applications, including epoxy-coated systems.

CPVC: Resists damage from chlorinated water. Should not be stored or installed in locations exposed to sunlight or other sources of UV radiation. Is incompatible with various construction and maintenance products, including specific caulks and sealants, cleaning solutions, pipe clamps and tape, lubricants and oils, waterproofing materials, spray foam, and firestopping materials among others.

PEX: Should not be stored or installed in locations exposed to sunlight or other sources of UV radiation. Has significant compatibility issues with some adhesive tapes, paints, greases, sealants, products containing acetone, and spray foam insulation, among others. Chlorinated water also will damage PEX pipe once the antioxidants added to the plastic are consumed.

PVC: Generally resistant to chemical damage, but exposure to certain substances can “permanently alter PVC by affecting its base resin or polymer molecules through reactions such as crosslinking, oxidation, or substitution. This can make it unrestorable even after the chemical is removed.” Products affecting PVC pipe include certain adhesives, cleaning fluids, degreasers, paint thinners and removers, lacquers, and coatings, among others.

Teams wishing to switch pipe types should consult closely with manufacturers to evaluate whether substances in other building systems – or those used for maintenance of such systems – could damage pipes.

Health Considerations for Value Engineering

It’s well known that volatile organic compounds (VOC) off-gassing from many products can degrade indoor air quality. This example offers a useful analogy for the ways plumbing choices may similarly impact occupant health, and building project teams should consider them when specifying piping materials.

During and immediately after installation of pipes, the health effects from pipe materials derived petrochemicals are nearly identical to those of products such as paint or synthetic carpeting. These types of pipes – and the adhesives used to join them – emit substances that can be inhaled by workers installing the pipe, increasing risks of cancer and liver damage.

Once plumbing is placed in service, a different class of issues becomes significant. Instead of air, however, water becomes the transfer medium. For buildings like schools that may go unused for days and weeks at a time during breaks, plumbing systems can harbor growth of opportunistic pathogens such as legionella bacteria. But plumbing in all types of buildings exposes occupants to substances they can ingest. This is because piping materials interact with water, producing byproducts that occupants can ingest.

Leaching from Pipes and Health Impacts

Chemical interactions between water and piping materials — typically oxidation — and the principles of osmosis mean all piping materials leach substances into water to some degree. The disastrous impacts of lead pipes provide sobering evidence of how serious leaching can be, posing a public health threat in thousands of communities.

Some materials are far safer than others, however, so teams evaluating plumbing choices need to consider leaching. This proves especially true for potable water supply and distribution, as health impacts are most immediate

from these systems.

Here’s an overview based on current research:

Cast iron: Pipes made of iron may release small amounts of oxidized metal (rust particles) into water. This rust may discolor the water and produce a metallic taste. Industry standards consider the “aesthetic limit” for iron to be 300 ppb. At concentrations higher than that, water will take on a brownish hue and a metallic taste. Similar to copper, the health effects of iron consumption at low levels are benign for most.

Copper: These pipes leach traces of copper at low levels that are generally regarded as safe. Humans consume copper from a number of foods, including whole grains, dark chocolate, and shellfish. Copper is an essential nutrient to maintain blood health and support muscle elasticity; this is especially true for the heart. Few individuals will suffer impacts caused by leaching from lead-free copper pipe and fittings. Only those affected by Wilson’s Disease, a health condition in which the body does not regulate copper, should have cause for concern. The limit for copper is 1,300 ppb, but average levels in North America range from 20- 75 ppb; much less than what is considered unsafe.

Plastic: Leaching from plastic pipes has been well documented. In 2018, a comprehensive study found 163 substances leached from plastic piping, including known human toxins and carcinogens such as benzene, which is regulated at just 5 ppb. As concerning, 74 of the leached substances are not currently regulated, meaning their effects on human health are unknown.

Microplastics

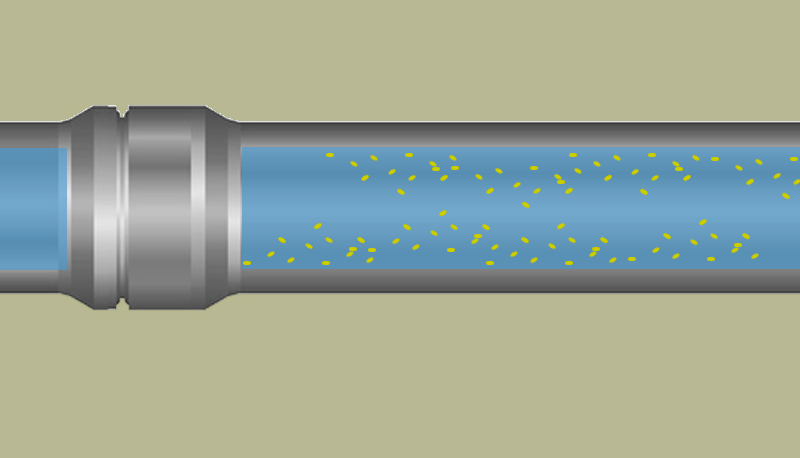

Plastic pipe, fittings, and the chemical solvents and adhesives used to bond and seal them all use complex chemical blends, hydrocarbons, and other additives. These substances leach from pipe walls over time, especially in plumbing exposed to heat or hot water. The effects of additives used by water companies to disinfect drinking water also can interact with chemicals in the plastics, producing secondary chemicals that are not well understood.

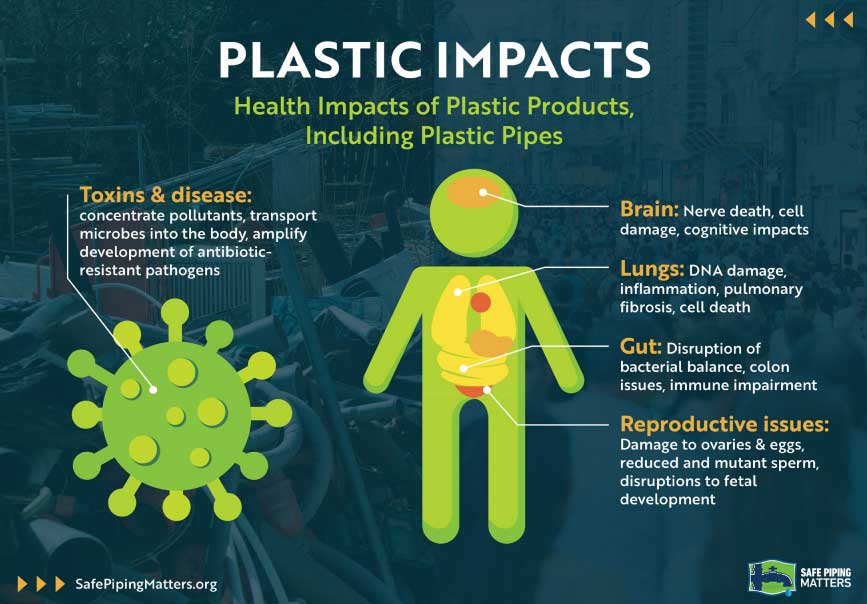

Furthermore, a report on water distribution systems that is currently in peer review shows that PVC and PE pipes shed microplastics (MP) and nanoplastics (NP) into potable water. The research found that these commonly used plastic plumbing materials crack and peel “relatively quickly” as they age. This degradation occurs as plastic compounds interact with water and the additives used for disinfection, releasing particles of plastic. When people ingest the MP and NP flaking from plastic pipes, it adds to their already significant exposure to plastic pollution. Microplastics have physical and chemical properties that can create serious health impacts, including gut disorders, lung damage, reduced cognition, and lower fertility.

GUT IMPACTS: altered microbial balance, reduced immune protection, and colon damage.

LUNG IMPACTS: Changes to lung cell DNA, tissue inflammation and damage, and accelerated rates of cell death.

BRAIN/COGNITIVE IMPACTS: Neurotoxic effects on brain cells, disruption of cognitive function and short-term memory (shown in mice studies), and increased vulnerability for neuronal disorders such as Alzheimer’s.

REPRODUCTIVE IMPACTS: Changes in ovary struc[1]ture and formation of ova, sperm defects, higher rates of adverse pregnancy outcomes, and disrup[1]tions to fetal development.

Environmental Impact and Sustainability Considerations

Environmental impact should be a primary consideration for all material selection, including and especially value engineering. In 1987, the United Nations Brundtland Commission defined sustainability practices as “Meeting the needs of the present without compromising the ability of future generations to meet their own needs.”

For the design and construction industry, that means moving away from things produced in a linear way – consuming materials and creating trash – and replacing them with circular materials that can be reused. To understand how the main types of piping stack up, we need to consider what happens at all stages of a pipe’s lifecycle, from making the materials, through installation and operation, plus what happens after that: do the plumbing materials have a life after use?

For the design and construction industry, that means moving away from things produced in a linear way – consuming materials and creating trash – and replacing them with circular materials that can be reused. To understand how the main types of piping stack up, we need to consider what happens at all stages of a pipe’s lifecycle, from making the materials, through installation and operation, plus what happens after that: do the plumbing materials have a life after use?

Cast Iron: Mining and refining iron has impacts and produces a carbon footprint. In addition, the heavier weight of iron pipe adds to the energy used to transport it. However, it is a circular material, and the industry has well-established processes to gather pipes, reclaim the materials, and use them again. Cast-iron pipe contains up to 96% recycled content and are themselves recyclable. Recycling rates stand at above 60% according to the Iron & Steel Institute.

Copper: Like all metals, the extraction of copper ore significantly impacts the environment by disrupting the areas around mines, generating tailings and other waste products. Refining ore into ingots and forming it into products also uses energy. Once that copper is made, however, it can be used again and again. In use, copper piping lasts decades, often longer than the life of the building in which it is installed. Further, the ability to solder and braze copper makes repairing pipes much easier. After use, copper pipe keeps 95% of its value, and studies estimate that two-thirds of all copper ever extracted is still in circulation today. Reusing these resources not only lowers the need to extract more material, it also reduces the energy needed to make new products. Analysis shows energy savings of 85%.

Plastics: The extraction and production of plastic also produces serious impacts. Plastic comes from fossil fuels, using oil and natural gas to generate the pellets that become feedstock for making pipes and other products. Plastic manufacturing has exploded over the past 30 years & the UN projects that impacts from production will grow a further 5X by the end of this decade. The most significant difference of plastic pipes comes at the end of product life. Virtually all plastic is engineered for single use. The recycling rate for plastic pipes is close to 0%, so all that material gets landfilled, adding to plastic pollution, or it gets incinerated, increasing carbon and other emissions.

Looking at the materials from a sustainability perspective, it’s clear that making any kind of pipe has an impact. How they stack up in the disposal phase is the real area of difference. Cast-iron and copper are circular by their nature. By contrast, plastic pipes are not.

Additional Considerations

Liability Considerations

The vital roles that plumbing systems play in building function and safety amplify the risks and liability associated with failures. Consider these potential scenarios:

- If substituted for copper, PEX pipes leach chemicals and cause de-zincification of brass fittings and compromising seals in a water-distribution system. Resulting slow or catastrophic leaks cause extensive damage in walls, ceilings, and floors throughout the building. Here, the specifying party – or the party responsible for making a substitution – could be found to be at fault.

- A section of PVC pipes sags due to inadequate support, creating a “belly” that prevents draining. The less-rigid PVC had been used instead of cast iron. The resulting backup of black water could cause extensive physical damage along with biological and health hazards in part or all of a structure, rendering it unsafe for use. The installer, contractor, and specifying party all could have responsibility, depending on the circumstances.

- Excess application of cement to a CPVC fire-sprinkler system results in plugged pipes. Such a situation could make the system fail – or prevent it from activating – in the event of a fire, vastly increasing damages and putting lives at risk. Both would expose installers and contractors to liability for failing to follow manufacturer-specified procedures.

If substituted materials, incorrect installation, or faulty maintenance are found to be at fault, insurance companies can subrogate (transfer) most or all property losses to the parties found responsible, including architects, engineers, and contractors. Injury or loss of life may bring additional legal consequences to responsible parties.

Acoustical Performance

The intermittent rushing sound of liquids moving through plumbing stacks can be distracting and disturbing, so teams designing buildings where occupants will be sensitive to sound should consider acoustics when selecting pipe materials.

The intermittent rushing sound of liquids moving through plumbing stacks can be distracting and disturbing, so teams designing buildings where occupants will be sensitive to sound should consider acoustics when selecting pipe materials.

This includes residences, schools, hotels, hospitals, senior-living facilities, and offices, among others. Dense materials such as cast iron are 750% more effective than plastic materials in terms of sound attenuation, according to one acoustics study.

If designed into the project early, sound baffle systems may abate the increased noise from materials such as PVC. Retrofit solutions prove to be less effective.

Conclusion

Designing Buildings Wiki has an excellent summary of value engineering, including best practices as they should be applied to construction. The core message they deliver is to remember the relationship between cost and value to “avoid mere cost cutting.”

Designing Buildings Wiki has an excellent summary of value engineering, including best practices as they should be applied to construction. The core message they deliver is to remember the relationship between cost and value to “avoid mere cost cutting.”

For plumbing systems, these considerations include calculating all costs of installation and maintenance, as well as avoiding detrimental tradeoffs related to safety, health, durability, resilience, and sustainability.

Here are some key ideas to remember:

- Safety: The use of combustible pipe materials increases complexity of firestopping and increases the frequency of installation errors, compromising the integrity of fire barriers.

- Durability: More flexible and lightweight materials often require more materials and labor to install correctly: more hangers when installed aboveground and more support when buried.

- Resilience: More reactive materials can be affected by a wide range of chemicals and environmental conditions that can degrade their strength.

- Health: Contamination of water from leached material can impact a wide range of bodily systems. This is particularly true of many chemicals.

- Sustainability: Producing all types of plumbing materials has environmental and carbon impacts. Circularity is the main area of differentiation.

- Liability: Design and construction teams can face significant liability if a plumbing system fails due to inadequate materials or installation methods.

- Acoustics: Building occupants may demand changes to plumbing systems if they make disturbing amounts of noise.